Pattern Data Hierarchy Concepts

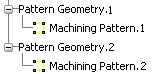

A machining pattern comprises two sets of data:

- Pattern geometry: Hole positions/axes, top element. The pattern geometry is visible in the work area and is editable in a dedicated editor.

- Pattern usage or technology data: Ordering mode, jump distance, local entry/exit distances, local depth, and activate/deactivate status.

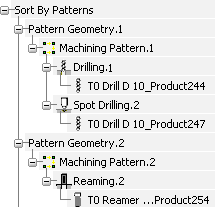

Information between pattern geometry/technology data and machining operations is shared in the Manufacturing View (Sort by Patterns or Sort by Machining Features). Both views have a similar presentation, but properties associated to the elements differ. Edition and sharing of data are available at each hierarchy level.

The general presentation is as follows:

In the example above, the three machining operations share the same geometry but control it through their own technology data (for example, specific jump distances).This is the way to overload technology data on the same position/axis data: This data cannot be moved to the operation data structure.