Flange Clocking Cases and Results | ||||

|

| |||

Pre-Condition:

Combination of supported piping part types:

- Piping Flange - Pipe - Piping Flange

- Piping Flange - Pipe - Piping Elbow

- Piping Flange - Pipe - Piping Tee

Planning the piping parts and pipes (As a manufactured part) from the Heavy Industry Manufacturing app and piping parts must connect to contextual links.

Note:

- Supported types in piping part category as piping flange, piping elbow, and piping tee

- For the correct result, define correctly all the axes in the above types.

- In the connection as, flange - pipe - tee (connected in the branch hole), case, this app supports only the flanges that have holes with the same distance from each other.

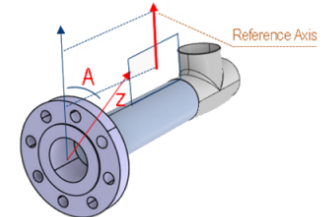

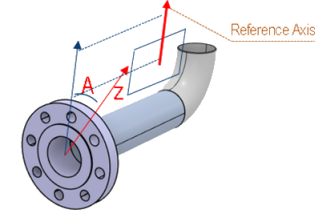

Computation Basis

The flange clocking angle computes always against the part direction that assembles on the other side.

The piping part direction, which locates on the start of a pipe, is the Reference Axis: 1.

If there are no piping parts or no supported piping parts, the direction of the first bend feature or intermediate macro takes as a Reference Axis.

Result: Angle; A value.

For bent pipes, the clocking angle computes after the end of a straightening operation. (2)

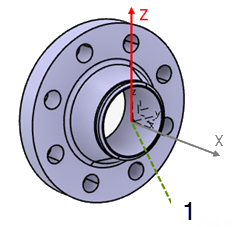

Computation Basis – Piping Flange

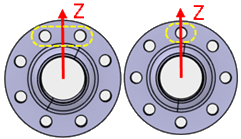

The flange rotation angle computes based on the Z direction of the axis used to create the port that connects with a pipe (1). Therefore, the Z direction defines a single or double hole.

Double or Single hole.

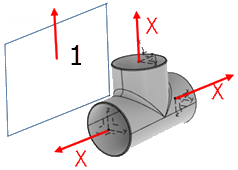

Computation Basis – Piping Elbow, Tee

To compute a plan for rotations, this uses all the X axes of the ports of the part.

Piping Elbow direction (1)

Piping Tee direction (1)

Piping Flange - Pipe - Piping Elbow result: (Angle); A value

Piping Flange - Pipe - Piping tee result: (Angle); A value