Machining/Slope Areas

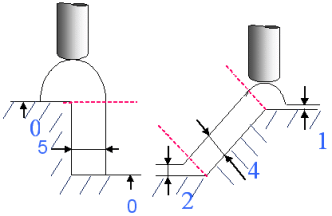

Machining areas are used to define different zones on a part: First you define the machining areas and then you assign a machining operation to each of them. This is an useful approach if, before you start machining, you are aware that the part has areas that will require different types of machining operation. Another feature of machining areas is their ability to be divided into horizontal, vertical and sloping areas and have a machining operation assigned to these areas.

A machining area can be:

- The whole part (for example, in roughing).

- A subset of the faces on the part.

- A subset of faces on the part with a limiting contour.

Limiting contours are not taken into account to compute the slope areas. However, they will be taken into account while computing tool paths on those slope areas:

- When you create a slope area, you associate one machining operation to each subset.

- The corresponding tool path is limited first by the defined subset and then by the limiting contour defined in the Machining/Slope Area Geometry tab page.

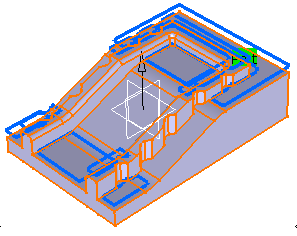

Horizontal and intermediate areas are defined as being inside the lines, whereas vertical areas are defined as being outside the lines, e.g.:

- Only vertical areas are shown, they are the areas not inside

the closed red contours:

- Only horizontal areas are shown, they are the areas inside the

blue closed contours: