3/5-Axis Converter Availability

Since the post-processor is able to process 5-axis tool paths, the

3/5-Axis Converter is a process that can be included in the

computation of the tool path to convert a 3-axis machining operation into a 5-axis one. The computed tool path avoids collisions and takes machine

kinematics constraints into account.

More... opens the 3/5-Axis Converter

dialog box that contains:

- Machining strategy tab

with: with:

- Global Modification

tab: Modify the tool axis of a tool path resulting from a machining operation without changing its contact point either by changing a 3-axis

tool path into a 5-axis tool path or by modifying a 5-axis tool

path,

- Collisions Checking

tab: Avoid collisions of the tool or the tool assembly within a 5

axis machining strategy. Collision checking is performed with the

selected geometry, not with the rough stock remaining from the

previous machining operation.

- Machine Kinematics

tab: Take those constraints into account.

- Macro tab

. .

The check box to start the 3/5-Axis Converter is available at

the bottom of the Strategy

tab

for the following commands:

- Roughing, with End Mill tools (spherical only).

- Sweeping, with End Mill tools (spherical and

torical), and Lens Mill tools.

- Advanced Finishing, with End Mill tools (spherical

and torical).

- Pencil, with End Mill tools (spherical only).

- ZLevel, with End Mill tools (spherical and torical),

Barrel Mill tools, TSlotter and Lollipops (TSlotter with spherical shape).

- Contour-driven, with End Mill tools (spherical and

torical), and Lens Mill tools.

- Spiral Milling, with End Mill tools (spherical and

torical), and Lens Mills tools.

- Isoparametric Machining, with End Mill tools

(spherical and torical).

- Profile Contouring with End Mill tools (spherical

only), and Lollipops (TSlotter with spherical shape).

Note:

Conical tools are not available.

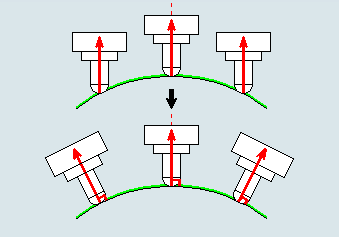

Global Modification

When selected, the Activate global modification check box

replaces all the tool axes of the tool path with the one selected in the Tool

axis mode list.

By default, Activate global modification is not selected.

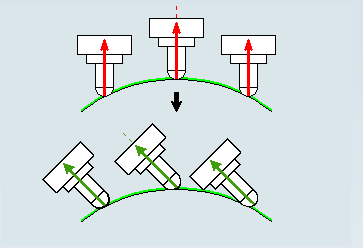

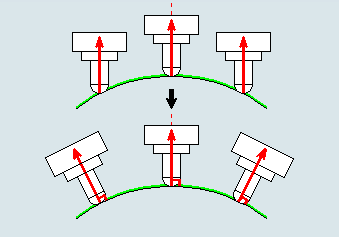

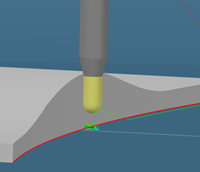

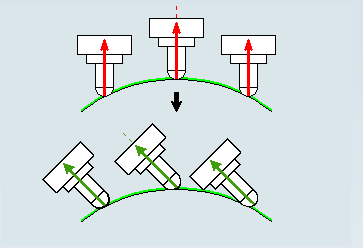

The upper part of the graphic zone of the dialog box represents the initial tool path

whereas the lower part represents the modified tool path.

Tool axis mode lets you

select a new tool axis mode from the list. Notes:

- When Rolling is selected, the

Macro tab in the 3/5 axis converter is

deactivated (Macros defined in the ZLevel operation apply).

- For other tool axis modes, the Macro tab is

displayed. The macro defined in the operation (active by default) can be

applied.

Fixed Axis

The tool axis arrow proposes a context menu:

- Select defines the tool axis.

- Analyze starts the Geometry

Analyzer.

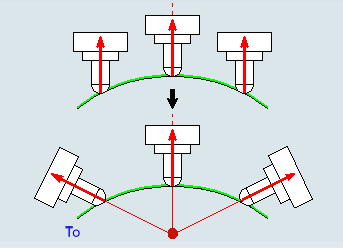

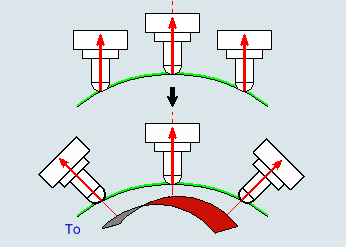

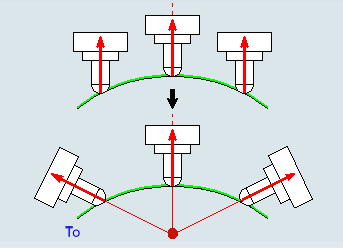

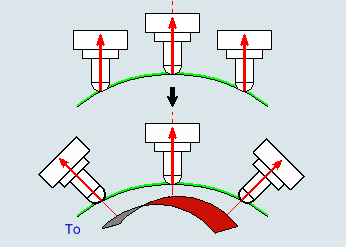

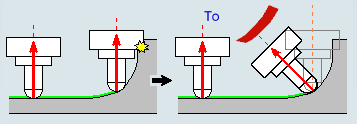

Thru a Point

The tool axis passes through a specified point.

- The label is a toggle to orient the tool axis To

the point or From the point.

- The point in the sensitive icon lets you select a point in the work area.

Thru a Guide

The tool orientation is controlled by a geometrical curve (guide), that must

be continuous. An open guide can be extrapolated at its extremities.

- The label is a toggle to orient the tool axis To

the guide or From the guide.

- The red curve in the sensitive icon lets you select a curve in the work area.

- Angle lets you specify a lead angle.

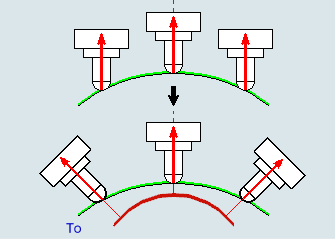

Normal to Part

The tool axis is normal to the part.

Angle lets you specify a possible frontal angle between

the tool axis and the normal to the part.

Fixed Angle

The new tool axis forms an angle with the initial tool axis.

- Angle

lets you specify this fixed angle.

- Privileged angle with the

tool path defines the angle a plane defined by the

direction of motion (Frontal angle) or in a plane

normal to the direction of motion (Lateral

angle).

Normal to Drive Surface

The new tool axis is normal to the drive surface.

Angle lets you specify a possible lead angle.

Note:

Use a smooth surface as the drive surface.

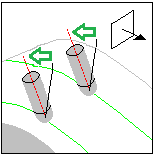

4 Axis

Converts a 3 axis or 5 axis tool path as follows:

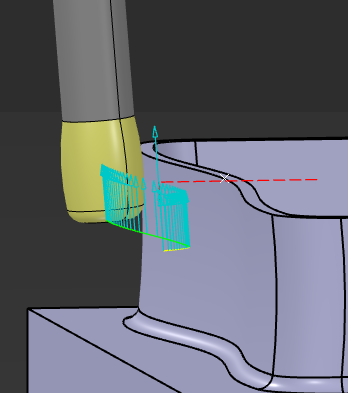

Rolling (with Barrel tool only)

Only Barrel Milling tools are supported.

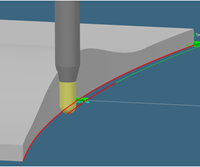

For each cutting point, the Rolling (with Barrel tool only) tool axis

mode positions the tool on the contact point position. Milling with the large

radius provides a good quality and increases the distance between passes, thus

reducing the machining time.

Associated parameters are:

- Max discretization angle to control the tool axis

variation along complex geometry. It is used to add more tool positions

(points and axis) if value is exceeded.

- Max tilt angle: Controls the tool tilt when the

slope angle of the wall decreases.

- Contact point position: Specifies the initial

contact point position, defined as a ratio of the barrel arc length.

- Contact: Defines the contact position option to

avoid collisions in undercut areas..

- Tilt Side: Defines the tilt side of the tool

according to the tangent motion and the initial tool axis.

Collisions Checking

Clear the check box Activate collisions checking if you do

not want to perform a collision checking.

By default, the collision checking is active.

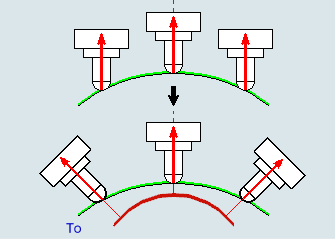

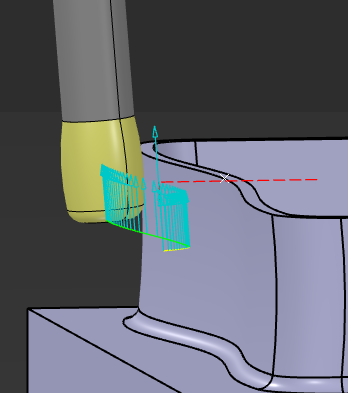

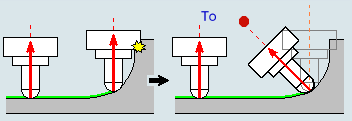

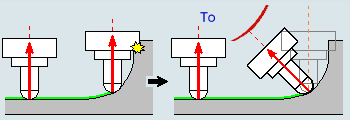

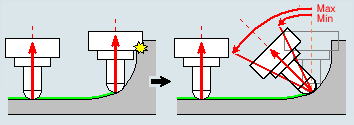

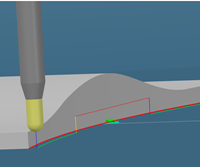

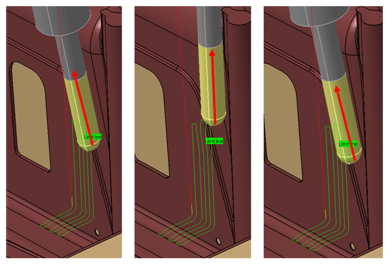

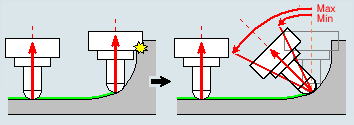

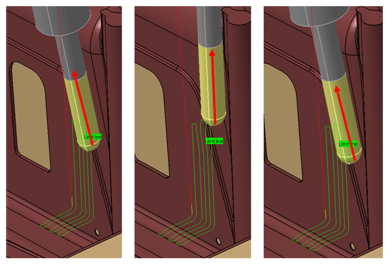

The left part of the graphic zone in the dialog box represents the initial tool path

whereas the right part represents the modified tool path that avoids collisions.

You can perform the collisions checking on:

- The Part.

- The Check.

- The Design Part of the Part Operation. In that case, make sure that you have selected a valid Design

Part in the Part Operation.

By default:

- Part is selected.

- Check is selected.

- Design Part is not selected.

Note:

In a Profile contouring operation, you cannot select a

part. Select the Design Part (PO) check box and make sure

it exists in the Part Operation.

Tool axis mode lets you select a new tool axis mode from the

list. It is applied to the points in collision found.

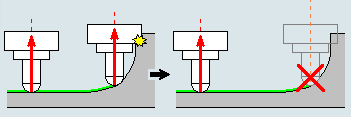

None

The tool axis is not modified, the tool path stops before the collision

point, and the corresponding portion of tool path is removed.

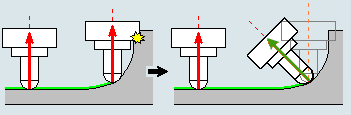

Automatic

The tool axis is automatically computed to avoid collisions.

Normal to Drive Surface

Note:

Use a smooth surface as the drive surface.

More

More... gives you access to more parameters for the above

tool axis modes:

- For all tool axis modes except None:

- Max discretization angle specifies the

maximum angular change of tool axis between tool positions. It

is used to add more tool positions (points and axis) if value is

exceeded.

- Minimum

length specifies the minimum distance that must

exist between two collision points to allow the modification of

the tool axis between those two points.

- For the tool axis mode Normal to part,

Angle lets you specify a possible angle

between the tool axis and the normal to the part.

- For the tool axis mode Fixed angle:

- Angle lets you specify the fixed angle.

- Privileged angle with the tool path

defines the angle a plane defined by the direction of motion

(Frontal angle) or in a plane normal

to the direction of motion (Lateral

angle).

- For the tool axis mode Automatic:

- Minimum angle and Maximum

angle define the range within which the tool

axis can vary.

- Step angle defines the computation step

used to find the optimal angle to avoid collisions. The smaller

the Step angle, the longer the

computation time.

- For the collisions checking strategy Automatic and the tool axis

mode Rolling (with barrel tool only):

- Contact point position range specifies

the range of the contact points. It is defined as a ratio of the

barrel arc length, centered on the initial contact point

position.

- Contact up to tool tip allows the contact

up to the tool tip when a collision is found. If selected,

Contact point position range is not

editable anymore.

Offset on tool defines

the offset applied on the tool to avoid collisions.

Offset on assembly

defines the offset applied on the tool assembly to avoid collisions.

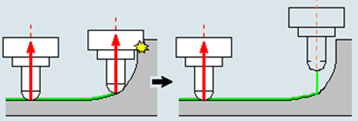

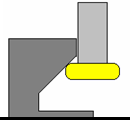

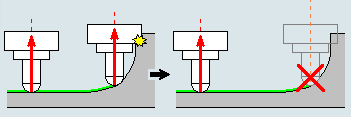

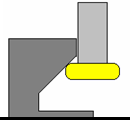

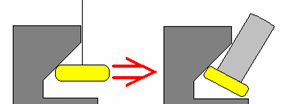

Undercut Milling is available only for a

ZLevel operation with a TSlotter tool or Barrel

Milling tool, and if Collision Checking is activated.

By default, Undercut Milling is not selected.

The ZLevel operation takes the tool body into account to

compute the tool path.

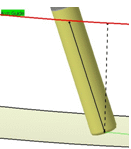

In

the image above, the tool with its body cannot machine more material: The tool

body is in collision. Undercut Milling computes the tool path with a quasi-null

tool body.

Undercut Milling + 3To5-Axis Converter.

Machine Kinematics

This tab lets

you correct problems encountered with respect of the machine kinematics.

By default, Optimize rotary

DOF,Correct out of limit points, and

Correct large angular variation on rotary DOF are not

selected.

Notes:

- If problems subsist after computing the tool path with those options, a

message is displayed.

- These corrections apply to the tool path of the current machining operation.

- The machine configuration on the first point of the current machining operation is seen as the result of a motion from the Home position to this first

point. Thus, it may differ from the actual one, resulting from previous machining operation and machine instructions.

- Angular variations between two points cannot be detected on the first point

of the tool path, because the position of the machine before this point is

unknown.

Optimize Rotary DOF

This check box is available if:

- The check box Activate global modification in the

Global modification

tab is not selected,

- The Tool axis mode in the Collisions

checking

tab is defined as Automatic.

Optimize rotary DOF:

- Supports only MTB milling machines,

- Does not support Mill-Turn or generic machines,

- Does not support interchangeable heads.

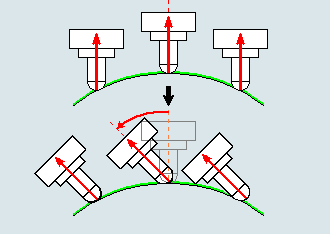

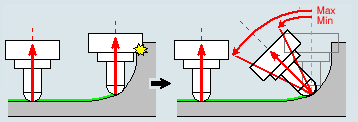

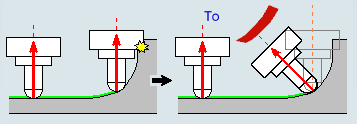

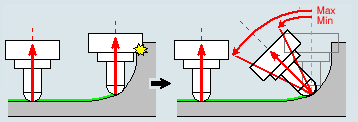

When selected, Optimize rotary DOF minimizes the

variations of rotary degree of freedom, as well as the tool axis variations:

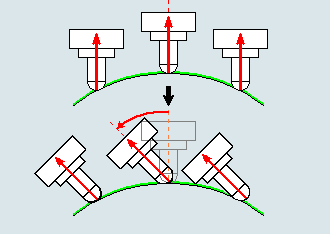

- On each detected collision point, the 3/5-axis converter may generate a

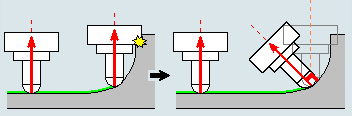

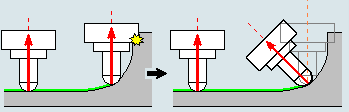

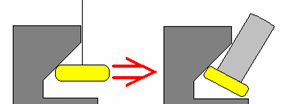

tool axis variation to avoid the collision.

- To avoid a collision, the original 3-axis tool path is temporarily

converted to a 5-axis tool path. It then reverts to 3-axis, before being

converted again to 5-axis as shown in the image below. The variation

shown in the middle image is not useful.

- When selected, Optimize rotary DOF avoids those

tool axis variations:

- The machine does not have to slow down to cope with the tool

axis variations,

- The machine output is of better quality since the machine has a

linear and constant behavior.

Correct Out of Limit Points

When this check box is selected, the points out of limits are removed:

- If the point is out of limits in the X, Y or Z-Axis, it is removed.

- If the point is out of limits in the A, B, or C-axis, the tool axis is

corrected and locked in the position limit.

- If the point with the corrected axis is in collision, the point is

removed.

Correct Large Angular Variation on Rotary DOF

If between two points of the tool path, the

variation on a rotary DOF (angular join of the machine) exceeds the

Maximum variation, you can select one or several

check boxes to modify the machine configuration. When you select several check

boxes, the most appropriate one is applied to any given point.

- Linking macro:

The modification is done within the existing linking macro of the tool

path.

- Tool pass: When

the tool is in contact with the part, you can define a

Fanning Distance.

Note:

Entering 0mm deactivates the

Fanning Distance.

- Retract macro: A

retract pass is added to reconfigure the machine.

In

addition, you can define the Maximum discretization on

the rotary DOF: If an angular variation between Maximum

variation and Maximum discretization is

detected between two points, new points are added to the tool path.

The status of the Machine Kinematics checking is displayed

in the Activities Process Tree, in a dedicated column.

Path Closed with Macros

When collision points found on the tool path are removed, the tool path must be

closed. This tab lets

you do that with Approach, Retract, and

Clearance macros.

|

with:

with:  .

.