-

From the Surface Machining section of the action bar, click Contour-driven

. .

A Contour-driven entity is added to the manufacturing program.

The Contour-driven dialog box opens at the Geometry tab

:

-

Still in the Geometry tab:

- Right-click the red area of the icon,

- Select a part,

- Click OK in the Face Wizard to confirm your

selection and redisplay the dialog box.

-

Go to the Machining Strategy tab

and select Between contours. and select Between contours.

-

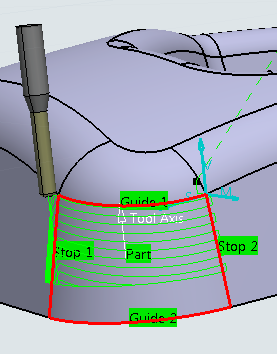

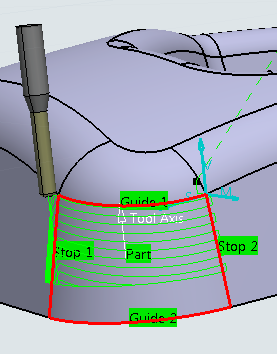

Go to the Radial tab:

- Select Constant 3D as the stepover strategy.

- Select the guides and stops.

Note:

According to the stepover selected, stops will be requested or not.

-

If necessary, set the distance between paths.

- As a Sweeping Strategy, select From guide 2 to guide 1

- Go to the Tool tab

to select a tool. to select a tool. -

Click Display or

Simulate to check the validity of the machining operation.

The result is of an equal distance on the part surface from guide 2 to guide 1.

Note:

The bottom of the machined area and how the paths remain perfectly parallel to each

other but because of the shape of the surface they finish gradually on Guide 1.

-

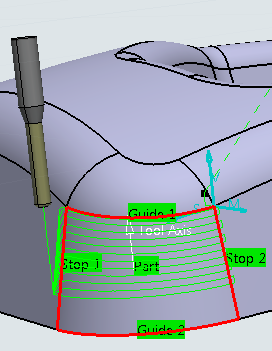

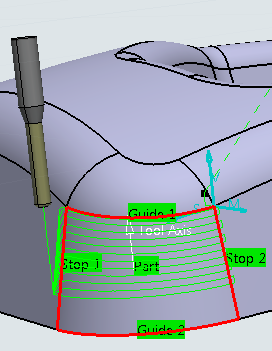

With the same parameters, switch to Maximum 3D and click Display or

Simulate.

There is a variation in the distance between the paths on the surface but the paths

respect both guide 1 and guide 2. There is no gradual finish on Guide 1 as there was with

Constant 3D.

|

.A Contour-driven entity is added to the manufacturing program. The Contour-driven dialog box opens at the Geometry tab

.A Contour-driven entity is added to the manufacturing program. The Contour-driven dialog box opens at the Geometry tab :

:

and select Between contours.

and select Between contours.

to select a tool.

to select a tool.