- From the Surface Machining section of the action bar, click Spiral milling

. .A Spiral milling entity is added to

the manufacturing program.

The Spiral Milling dialog box opens at the Geometry tab  .

-

Still in the Geometry tab:

- Click the red area in the sensitive icon and select the part in the work area.

The faces must be connected to each other.

- Double-click anywhere in the work area to confirm your selection and redisplay the dialog box.

-

Select the Machining Strategy tab

and make sure that Horizontal area selection is set to

Automatic. and make sure that Horizontal area selection is set to

Automatic.

- Select the Tool tab

to choose a tool. to choose a tool. -

Click Display or

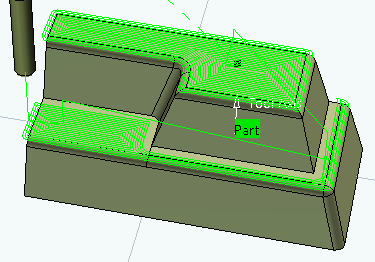

Simulate to check the validity of the machining operation.

- The tool path is computed.

- A progress indicator is displayed.

- You can cancel the tool path computation at any moment before 100% completion.

- Click OK in the Display or

Simulate dialog box, and again in the main dialog box to create the machining operation.

The tool path is created.

|