- From the Surface Machining section of the action bar, click Sweeping

.

.

A

Sweeping entity is added to the

manufacturing program.

The dialog box opens at the

Geometry tab

.

-

Still in the Geometry tab:

- Click the red area in the

sensitive icon

and select the part in the work area.

- Double-click anywhere in the work area to confirm your selection

and redisplay the dialog box.

-

In the Radial tab, set the Maxi. distance between

pass as required.

- Select the Tool tab

to choose a tool.

to choose a tool. -

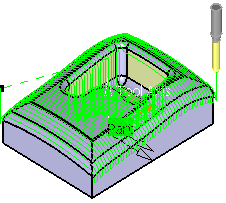

Click Display or

Simulate

to check the validity of the machining operations.

to check the validity of the machining operations.

- The tool path is computed.

- A progress indicator is displayed.

- You can cancel the tool path computation at any moment before 100%

completion.

- Click OK in the Display or

Simulate dialog box, and again in the main dialog box to create the machining operations.

The tool path is created.

The top surface and the bottom of the pocket are sweep-machined.