Verifying Consistency Between Programming and Planning | |||

| |||

Click Play to watch the video:

-

From the Point Fastening section of the action bar,

click Planning Programming Consistency Check

.

.

The Planning Programming Consistency Check dialog box appears.

The Context displayed is based on the current ASO when Planning Programming Consistency Check is clicked.

To view a different Context, click and select a robot or

manufacturing cell. Note: If you select an object other than these two types, the first parent manufacturing cell of the selected occurrence is defined as the Context.

and select a robot or

manufacturing cell. Note: If you select an object other than these two types, the first parent manufacturing cell of the selected occurrence is defined as the Context.The Planning Programming Consistency Check dialog box provides two views of the current data:

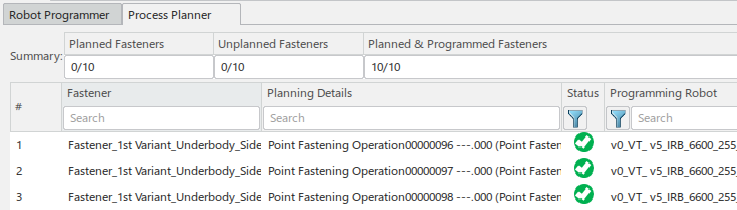

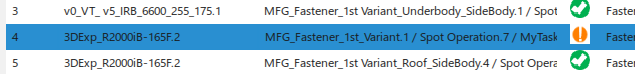

- The Robot Programmer tab lists the

Robots and indicates the Status of

the Programming Details, and the Assigned

Fastener for each spot move. You can program fasteners and reassign

spot moves in this tab.

- The Process Planner tab provides a read-only view of the

data from the perspective of the planner, listing the Planning

Details for each Fastener and the programming

Status for each.

The Status column indicates the current status for a given spot move. Click

in the titlebar

to view the Status Legend.

in the titlebar

to view the Status Legend.

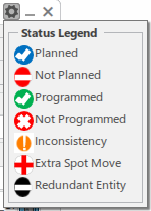

- Planned: The fastener has a point fastening operation

planned, but there is no task containing a spot instruction for the given point

fastening operation. A point fastening operation is considered planned when it has a

robot assigned to it. Note: This status is available only in the Process Planner tab. It is replaced by Not Programmed in the Robot Programmer tab.

- Not Planned: The fastener does not have a point fastening operation planned.

- Programmed: The fastener has a point fastening operation planned, and a robot task with a spot operation for that point fastening operation exists.

- Not Programmed: The fastener has a point fastening

operation planned, but there is no task containing a spot instruction for the given

point fastening operation. A point fastening operation is considered planned when it

has a robot assigned to it. Note: This status is available only in the Robot Programmer tab. It is replaced by Planned in the Process Planner tab.

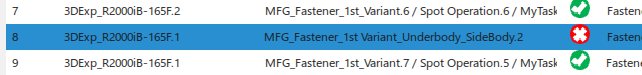

- Inconsistency: The assigned robot for the point fastening operation differs from the programming robot.

- Extra Spot Move: A spot operation exists in a task for the resource whose planning details are unavailable or deleted.

- Redundant Entity: Any row in the table not having one of the above status qualifications is considered redundant, such as a tag with a task instruction that has no corresponding planning information, or if a process planning operation exists for a tag, but the fastener is not available.

- The Robot Programmer tab lists the

Robots and indicates the Status of

the Programming Details, and the Assigned

Fastener for each spot move. You can program fasteners and reassign

spot moves in this tab.

-

To reassign a spot move, select it in the table:

-

In the Reassign Spot Move section, click Select

Robot

and select a robot in the work area. The Robot, Task, and

Trajectory are populated based on your selection.

and select a robot in the work area. The Robot, Task, and

Trajectory are populated based on your selection.

-

Click Commit

to confirm the

selection.

to confirm the

selection.

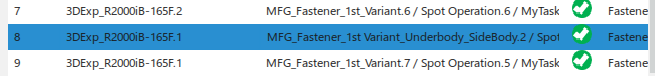

The spot operation and tag is moved from the source robot task to the target robot task.

The Status column of the selected move is updated. Note: You can click

Note: You can click to delete a selected spot

operation and associated spot weld.

to delete a selected spot

operation and associated spot weld. -

In the Reassign Spot Move section, click Select

Robot

-

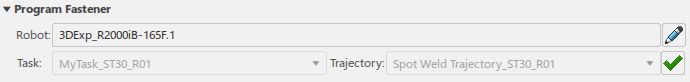

To program a fastener, select it in the table:

-

In the Program Fastener section, click Select

Robot

and select a robot in the work area. The Robot, Task, and

Trajectory are populated based on your selection.

and select a robot in the work area. The Robot, Task, and

Trajectory are populated based on your selection.

-

Click Commit

to confirm the

selection.

to confirm the

selection.

A manufacturing weld and spot operation are created in the selected robot task.

The Status column of the selected move is updated.

-

In the Program Fastener section, click Select

Robot

-

Click the Process Planner tab.

All modifications made in the Robot Programmer tab are reflected in the Status column of the Process Planner tab.

-

To export the Robot Programmer or Process Planner table to an Excel spreadsheet, click

Save Table

.

A notification appears when the export is complete.

.

A notification appears when the export is complete.