Note:

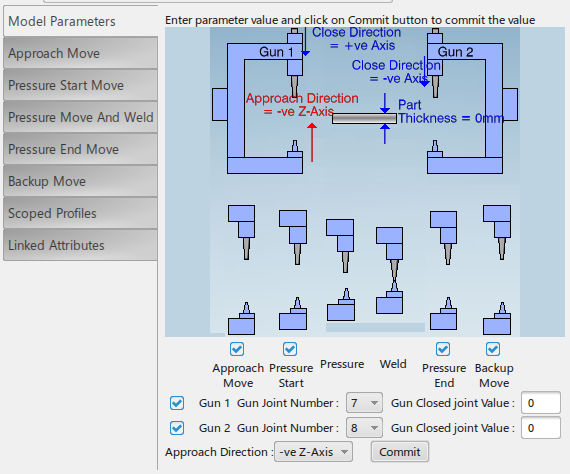

Some Servo guns may have two pair of welding tips.

These two pairs of welding tips are shown as 2 separate guns in all

the pictures for clarity purposes. If Gun 2 is unchecked

in the above dialog, all the parameters related to Gun 2 in the following

tab pages will be non-editable.