Creating a Spot Trajectory in a Process Planning Scenario

You can create a spot trajectory from a point fastening or general operation, and assign/unassign resources if there is no need to perform analysis via Auto Gun Search and Analyze Weld. You can also connect spot tags to point fastening operations when necessary.

-

From the Point Fastening section of the action bar, click

Create Spot Trajectory

.

.

You are prompted to select a general operation, point fastening operation, manufacturing cell, or robot.

-

Select one of the following:

- A general operation from the Behavior side tab.

- A robot in the work area.

- A manufacturing cell in the work area.

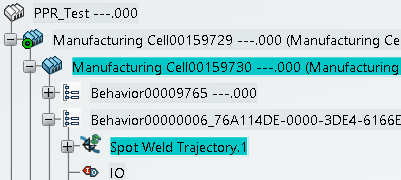

A process trajectory is created under the parent manufacturing cell of the robot assigned to the general operation, and also appears in the Behavior side tab.

Note: If a robot is not assigned to the selected general operation, a process trajectory is created under the manufacturing cell that has scope link with the parent system of the selected general operation, provided that general operation is either a To plan or a Rejected bucket operation.

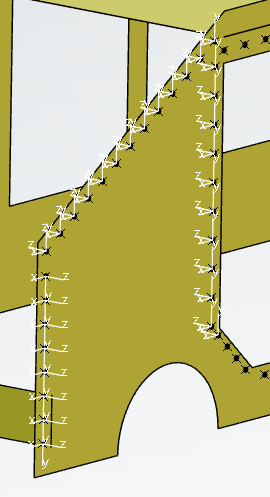

Note: If a robot is not assigned to the selected general operation, a process trajectory is created under the manufacturing cell that has scope link with the parent system of the selected general operation, provided that general operation is either a To plan or a Rejected bucket operation.A spot tag is created in the process trajectory for each point fastening operation under the general operation, and appears at each fastener location on the part.

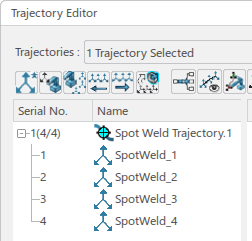

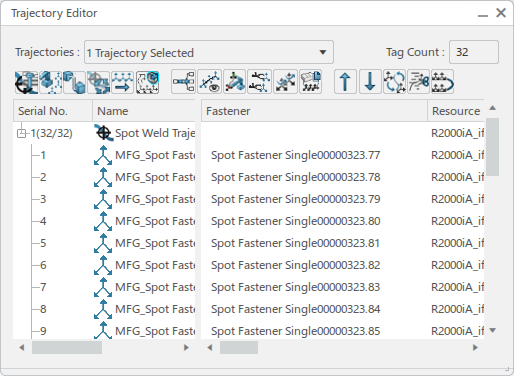

The Trajectory Editor panel appears, and is populated with the spot tags of the new trajectory.

Fasteners are highligted in the work area as you select them in the Trajectory Editor:

-

From the Trajectory Editor, click Add Spot

Tags

to create spot weld tags that are associated to a point fastening operation.

You are prompted to select a general operation or point fastening operation.

to create spot weld tags that are associated to a point fastening operation.

You are prompted to select a general operation or point fastening operation.Upon selecting a general operation, design fasteners implemented by the point fastening operations are accessed by traversing through the implement links. A process trajectory is created with manufacturing welds (spot tags) at the design fastener locations. The number of resulting tags equals the number of point fastening operations that successfully access the design fasteners.

Upon selecting a point fastening operation, the design fastener implemented by the point fastening operation is accessed by traversing through the implement link. A manufacturing weld (spot tag) is created at the design fastener location under the active process trajectory.

-

To assign or unassign resources for the trajectory, click Assign/Unassign

Resources

.

.

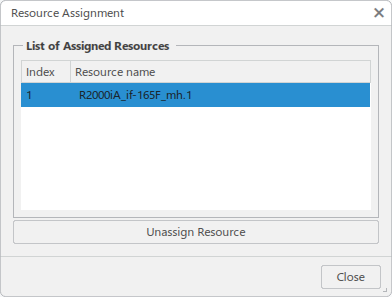

The Resource Assignment dialog box appears.

Click Unassign Resource to unassign a selected resource in the list.

If there are no resources in the list, you are prompted to select a resource in the tree or work area.

The selected resource appears in the list upon selection.

-

Click Reconnect Tag to Point Fastening Operation

to

reconnect a selected spot tag to a point fastening operation.

to

reconnect a selected spot tag to a point fastening operation.

Spot tags can require reconnection when a trajectory is uploaded from Robot Programming, or when analyzing the results of Compare and Transform

. You are prompted to select a point fastening operation to connect.

. You are prompted to select a point fastening operation to connect. -

Click Update Spot Trajectory

to

update the trajectory when changes have occurred in the design position of fasteners.

When the update is complete, a message appears that provides a report of updated elements.

to

update the trajectory when changes have occurred in the design position of fasteners.

When the update is complete, a message appears that provides a report of updated elements.