Synchronize Data with Planning

Click Play to watch the video:

-

From the Setup section of the action bar, click Synchronize Data with

Planning

.

You are prompted to select either:

.

You are prompted to select either:- An operation

- A system

- A manufacturing product

- An organizational resource

-

Select a general operation.

The Synchronize Data With Planning dialog box appears.

A 3D preview of the planning output generated is displayed.

- Planning operation indicates the operation that was selected.

- Location indicates the manufacturing cell where the manufacturing product is created.

- Manufacturing Product indicates the name of the manufacturing product that is created.

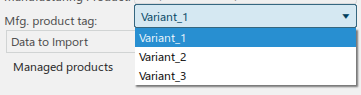

- Mfg. product tag allows you to select from a list of

variants that you have created.

If a Mfg. product tag is specified, the name of the manufacturing product and resource trajectory created is prefixed with the selected variant name.

New variants can be defined directly in the Mfg. product tag editor when Create a new manufacturing product is selected.

Note: Create a new manufacturing product appears in the dialog box when running Synchronize Data with Planning after an initial manufacturing product has been built.

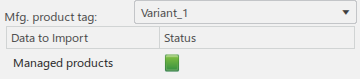

Note: Create a new manufacturing product appears in the dialog box when running Synchronize Data with Planning after an initial manufacturing product has been built.The status of a selected variant is indicated in green (up to date) or red (out of date).

-

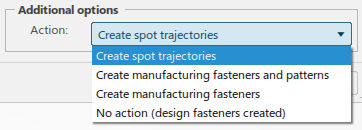

In the Additional options section, select Create

spot trajectories and click OK.

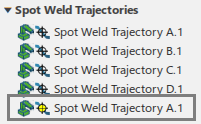

A new resource trajectory with design information is created:

The resource trajectory has a different icon

to

distinguish it from other spot trajectories, and is attached to the manufacturing

product. It has the same content as the process trajectory that is associated to the

selected general operation.

to

distinguish it from other spot trajectories, and is attached to the manufacturing

product. It has the same content as the process trajectory that is associated to the

selected general operation.The output manufacturing product is created under the manufacturing cell: