Applying Length Tolerance | |||

| |||

-

From the Formboard section of the action bar,

click LengthTolerance

.

.

-

Select any of the following objects:

- Device: The device is selected

- Support: The nearest segment extremity or route definition point is selected

- Protection Extremity: The nearest protection extremity is selected

- Segment Extremity: Segmentconnection point , cavity, or branch point

-

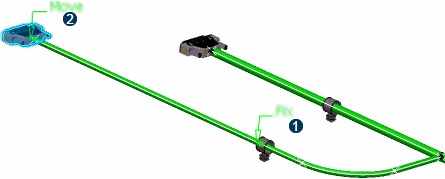

Select the required object to make it fixed object in the geometry.

The Fix tag appears on it. -

Select another object the to make it movable.

The Move tag appears on it.

Fix tag

Move tag Devices are always tagged as move.

Tip: You can double-click any of the tags to swap their positions. The Length Tolerance dialog box is also displayed. In the Value box, enter a value or use the arrows to change the value.

-

In the Value box, enter a positive value or a negative value to

specify the positive or negative tolerance value.

Note: You can also enter an equation.

-

Click OK.

The segment length is increased or decreased by the value specified. The tree shows the applied length tolerance to Segment.1

-

Right-click the segment and select Properties. .

The Properties dialog box shows that the LengthTolerance parameter is set to true

Notes:- You can apply more than one length tolerance value over different portions of the same segment.

- You can apply length tolerance to a flattened geometry extracted from 3D harness.

- If a segment, support, or protective covering linked with the length tolerance are removed during the synchronization, the effect of the tolerance is also removed.

- You cannot scale a segment to which length tolerance is applied.

- If both design length and flattened length are increased, the length tolerance value is maintained on the segment portion even after synchronizing the 3D flattened geometry. For more information, see Synchronizing the 3D Flattened Geometry.

Important: - If length tolerance is used on a flattened geometry not flattened in coarse mode, the result may not be what you expect.

- Length tolerance cannot be applied on a Roll section & vice-versa.