Levels of Definition

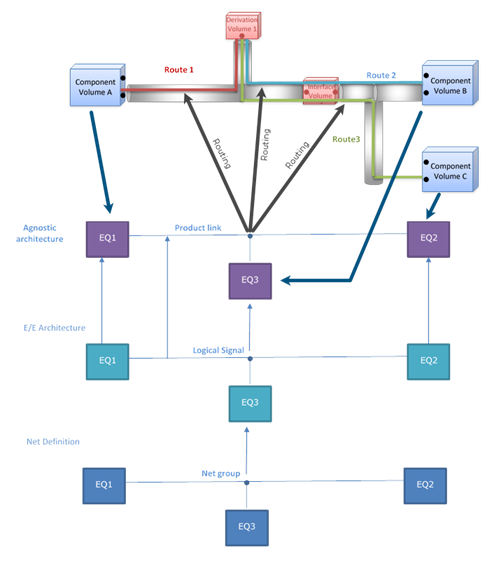

The net to wires process comprises four levels of definition:

- The system (agnostic) architecture

- The electrical architecture (EEW)

- The electrical net definition

- The electrical wiring definition

The following links between the objects of the different steps must be created to retrieve the following objects:

- The corresponding component volume node from a logical equipment of the system architecture

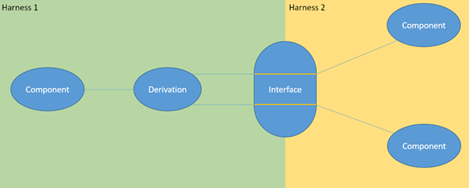

- The corresponding interface volume node from a logical Terminal Block container defined in the wiring definition

- The corresponding derivation volume from a logical Terminal Block of the wiring definition

- The implemented EEW Logical Signal from the net group of the net definition

- The implemented logical system architecture Signal from the EEW Logical Signal

- The implemented EEW equipment from equipment of the net definition

- The implemented logical architecture Equipment from the EEW equipment

This equivalent routing is, for each net group of a net, the routing of the corresponding

product link of the agnostic architecture in the 3D mockup: