About Thermoelectric Cooler Components | |

| |

Thermoelectric Cooler Structure

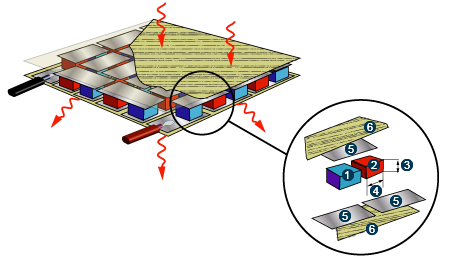

A TEC is a thin, chip-like device that connects to a power source. The device is composed of two plates (typically made from ceramic or aluminum) that sandwich together a set number of semiconductor pellets, as shown below.

![]() N-type semiconductor pellet

N-type semiconductor pellet

![]() P-type semiconductor pellet

P-type semiconductor pellet

![]() Pellet height

Pellet height

![]() Pellet width

Pellet width

![]() Metal linkages

Metal linkages

![]() Plates

Plates

There are two types of semiconductor pellets, negative and positive (that is, n-type and p-type). The n-type pellets are made from a material that is electrically neutral but has excess electrons occupying the valence shells of its atoms. The p-type pellets are made from a material that is also electrically neutral but has excess vacancies in the valence shells of its atoms. The pellets are daisy chained in an alternating pattern (for example, n-p-n-p) using metal linkages that alternate sides of the pellets. Each end of the daisy chain is soldered to a lead, such that the TEC can connect to a power source and ground.

There are no moving parts in a TEC, meaning it is ideal for solid-state applications.

Energy Transfer

TECs operate according to the Peltier effect; when you apply a voltage to a thermoelectric device, the current (DC) creates a temperature difference between the electrical junctions. In the case of a TEC, when you apply a voltage to the leads, heat diffuses from the metal linkages on one side of the TEC to the metal linkages on the opposite side of the TEC through electron transport. The heat transfer creates a "cold side" and a "hot side" of the TEC. The TEC's hot side must be positioned against a heat sink for the device to operate as expected. The TEC's cold side is positioned in a manner such that it is exposed to the heat source. The hot and cold sides of the TEC can be reversed by changing the direction of the current.

You can control the performance of a TEC with high precision by adjusting the voltage or current that you apply to the circuit.