Legacy - Defining the Stacking | ||

| ||

-

To select stacking options from the context toolbar, click Spot Fastener

Stacking

.

.

Option Description

Invert Direction Inverts the direction of the selected fasteners.

Direction Coordinates Changes the direction coordinates of the selected fasteners.

Position Coordinates Changes the position coordinates of the selected fasteners.

Automatic Stacking Automatically selects the parts that will define the stacking. You need to specify the size of the selection area you want to use.

Note: When dealing with spot, assembly and flexible fasteners, you can include or exclude fastener components from the computation performed by the Automatic Stacking capability. To do so, select or clear Take fastener components into account in the computation. For more information, see General.

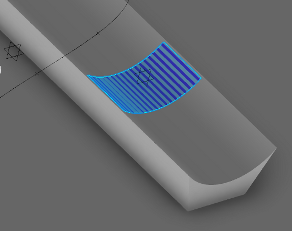

Cylindrical Mode Defines a cylindrical selection area with two manipulators. All the parts located between these manipulators will be selected as the fastened parts.

Note: Negative values assigned to limits are not supported by the stacking assistant.

Spherical Mode Defines a spherical selection area. All the parts intersected by this sphere will be selected as the fastened parts.

Remove Fasteners Removes the selected fasteners.

-

To specify the stacking, do one of the

following:

- Select the parts in the work area.

- Select one or more parts that are

already linked in the

Stacks of selected

points frame to add them to the

Stacks of selected

fasteners frame.

Note: You can add a part to enrich the existing stacking or remove a linked part. You can also click

to merge two stackings or

to merge two stackings or

to create a new engineering connection (MCX) for the

fastener instances set in your selection scope.

to create a new engineering connection (MCX) for the

fastener instances set in your selection scope.

- Click

Automatic

Stacking

to let the app select the parts.

to let the app select the parts.

-

Optional: To reorder the stacking, click the up and down

arrows.

Provided that the piloting part was set as Automatic, you can modify it using the reorder capability: if the parts are reordered so that another part becomes first in the list, the latter becomes the piloting part. However, if the piloting part was set as Manual, the reorder capability only changes the location of the piloting part in the list.

Tip: A hem icon in the Stacks of Selected Fasteners dialog box informs about the stacking parts. It contains: - An image showing the type of stacking:

-

Flat stacking: No part is duplicated, all stacking parts

are distinct.

Flat stacking: No part is duplicated, all stacking parts

are distinct.

-

Folded stacking: At least one part is duplicated.

Folded stacking: At least one part is duplicated.

-

- Text:

nT where

n

indicates the number of parts in the stacking (up to five

parts).

>5T: The stacking includes more than five parts.

- An image showing the type of stacking:

- Click anywhere in the 3D area to validate the stacking.

-

Click anywhere in the 3D area.

The fasteners are instantiated from the reference fastener with a locator patch projected onto the piloting part.

Important: Now that you have instantiated the locator patch, do not create additional constraints on the fastener.