Types of Mechanical Junction

The type of the mechanical junction specifies its role in setting and maintaining the position of a feature during assembly with respect to the mechanical interfaces.

Following are the types of mechanical junction based on its role during assembly:

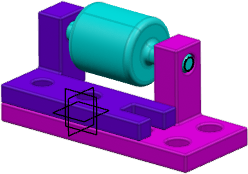

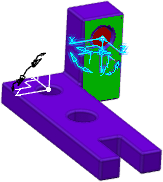

- Main Part: The mechanical junction that sets and maintains the 3D part in position as a component in an assembly. By default, the first mechanical junction is a main part mechanical junction.

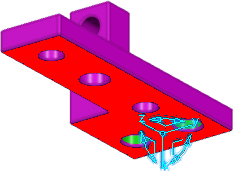

- Main Block: The mechanical junction that sets and maintains in position, or contributes to set and maintain the 3D parts in position as a sub-assembly component in an assembly.

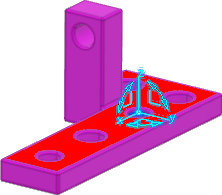

- Auxiliary: The mechanical junction that sets and maintains in position, or contributes to set and maintain other 3D parts in position as a component in an assembly. By default, the mechanical junction created after the first one is an auxiliary mechanical junction.

|

|

|

|

|

|