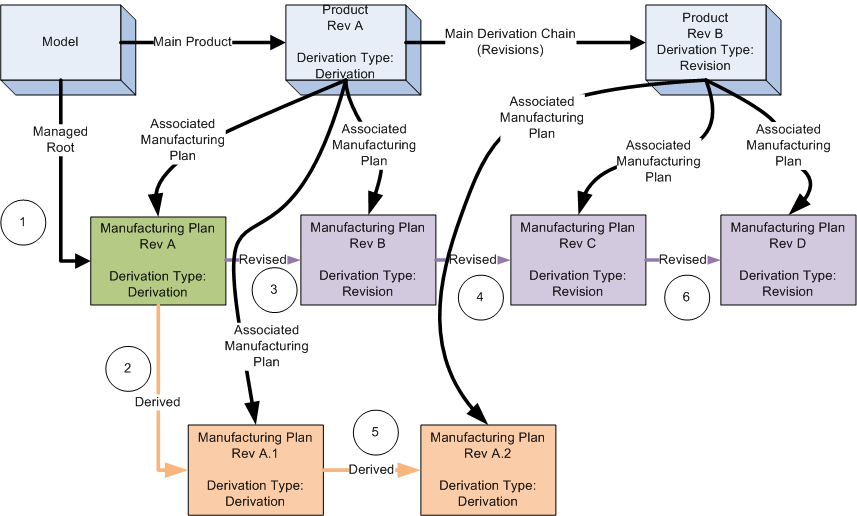

Manufacturing Plans, Revisions, and Derivations

All model versions have a revision level. The distinction between a revision and a derivation is how that model version is related to its parent. The Derivation Type attribute on the model version shows this information. Manufacturing plans work the same way; they all have revisions, and the Derivation Type attribute defines which type of plan it is.

- From the context of the model, create a new revision. Because this is the first manufacturing plan, it must be a revision and is called the Managed Root for the model. When you create the revision, you specify a model version, and the manufacturing plan is an Associated manufacturing plan for that model version. In this case, the model version is the initial derivation of the model.

- Select Manufacturing Plan A and create a derivation. The new plan is associated with the same model version.

- Select Manufacturing Plan A and create a revision. The new plan becomes an associated manufacturing plan for Model Version Derivation A and is associated with the same model version. Revisions form the main derivation chain for the manufacturing plans.

- Select Manufacturing Plan B and create a revision. The new plan becomes an associated manufacturing plan for Model Version Rev B and is associated with the same model version.

- Select Manufacturing Plan A.1 and create a derivation, and select Model Version Rev B as the Planned For Model Version. The new plan is a derivation, and associated with Model Version Rev B.

- Select Manufacturing Plan C and create a revision, select Model Version B as the Planned For Model Version.

This screen shows the Derivation page for a model for the above diagram. Notice that all of the names are the same but with different revisions. The original name was defined by the AutoName tool; subsequent revisions and derivations retain the name and change the revision, unless you explicitly change the name. The Display Name was manually edited.