When you create a pit case scenario, you specify the financial parameters that are relevant

to the processing of the commodity or commodities. These can include mining and processing

operating costs and revenue drivers such as the recovery percentage or the commodity

price.

You can choose from two block valuation modes: a simple valuation mode or a complex

valuation mode. Options for the block valuation mode are available in the Create

Scenario dialog box.

By default, the simple valuation mode is enabled.

By default, the simple valuation mode is enabled.

Block Value Calculation in Complex Valuation Mode

In the Scenario dialog box, you can use the toggle key to turn

Simple Valuation Method on or off. If you switch

Simple Valuation Method off, the multiprocessing mode is enabled

automatically. The block value is calculated using the commodities and processing methods

you specified with a more sophisticated algorithm.

This illustration describes how the block value is calculated when the multiprocessing

mode is enables; that is the Simple Valuation Method is switched

off for the scenario.

The table

below summarizes the input parameters and variables that are calculated when the complex

valuation mode is enabled ( Simple Valuation Method is turned off)

.

| Parameters |

Description |

MCostPerMass |

The mining cost per mass of extracted material |

PCostPerMass |

The mining cost per mass of materials |

PriceOfCommodity |

The price of a commodity |

RecoveryFraction |

The recovery faction for processing a commodity/product |

GradeOfCommodity |

The grade of a commodity |

PCostByCommodityUnit |

The extra cost per input unit of this commodity, when processing this rock

type using this method |

BlockMass |

The mass of the block |

CommodityInputMass |

The mass of a commodity input to a processing method, calculated by

BlockMass * GradeOfCommodity |

| Calculated variables |

Description |

BlockMCost |

Total cost of mining the block |

BlockMCost |

Total cost of processing the block |

BlockVal |

The net profit of the block |

BlockVal |

The revenue received from the block without subtracting any cost |

Case 1 Mill A Only

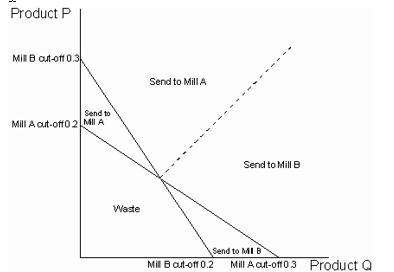

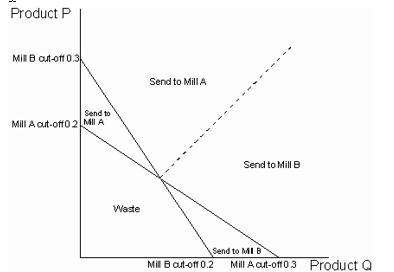

If we draw a line on the plane for all grade combinations that divides these between

profitable to be sent to Mill A from those that are not:

Case 2 Mill A and B Combined

In this case, we cannot use cut-offs to select material for each mill so as to give the

highest cash flow in all cases. The only option is to adopt a grade control system, which

is based on cash flows.

Although this is an artificial case, real cases can present as complex conditions,

especially when deleterious elements are involved.

Minimum and Maximum Acceptance Grade

The minimum and maximum acceptance grade controls the entry condition of the processing

materials.

When handling multiple commodities, if any commodity grades exceed the range of an entry

condition, then the block is rejected from processing— even when another commodity

satisfies the grade range.

This effect varies from the method that merges multiple commodities to equivalent

commodities.

In the Complex Valuation Mode, you cannot manually change the

cutoff grade to enforce the ore selection rule.

However, you can use the minimum acceptance grade, but the effect produced is different.

For example if the minimum grade is raised to higher than the marginal cut-off grade, then

the materials above the marginal cutoff and below minimum grade are not processed.

If the minimum grade is below the marginal cutoff, it does not enforce the low-grade

materials processing below the marginal cutoff, it does not impact the ore selection.

Options to Specify Economic Parameters

To specify economic parameters for calculating the block value during the pit

optimization, you can choose from the following valuation options:

- User-Defined block value. This option provides a standard

function to valuate materials in blocks. you enter financial data (price, cost) and

Pit Optimization

- Value Attribute block value. It is already precalculated and

exists in the block model. All you need to do is select the value attribute. For more

information, see Defining an Economic Scenario.

Options for the Ore Selection Methods

The block that is selected for processing within a pit case scenario is defined as ore.

The criteria that is used for defining the material destination is controlled by the

Ore Selection Method option. You can determine the ore selection

method from the following options:

-

Cash Flow that identifies the ore by the profit of the block

calculated according to financial parameters. The block value is calculated

implicitly. No additional parameters are required for this option.

-

Cutoff Grade that identifies the ore by a user-defined cutoff

grade. This overrides the implicit ore selection criteria.