About Matching | ||||

|

| |||

General Information

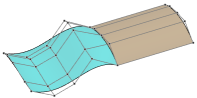

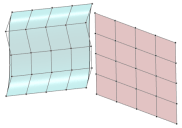

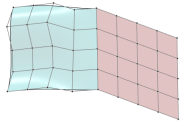

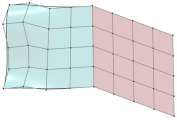

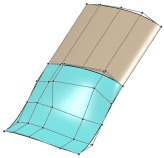

In the domain of Class A modeling, one of the key features is the matching between several objects and boundaries (like surface-surface match, or curve-surface match etc.). In general, the matching function modifies the control points to achieve a certain geometric continuity at the matched boundary (edge or point).

However, for Class A modeling, we have scenarios where the matching must not change any control points but only report that the match is not fulfilled anymore. You can now handle this by the use of the ICEM Design Experience matching constraint feature. As the command specifies the matching and computes the result, the soft parametric options give control of how the matching shall react.

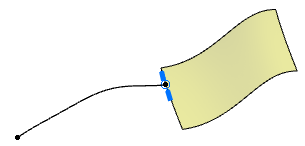

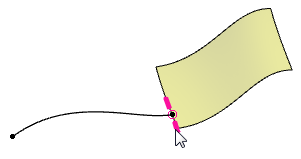

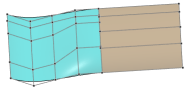

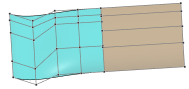

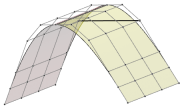

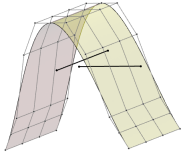

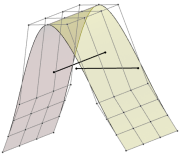

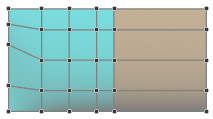

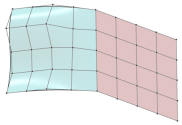

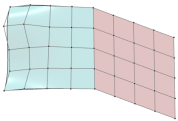

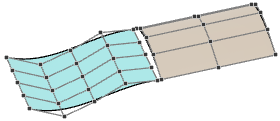

The first selected edge (surface matching) or point (curve matching) is the object (target) to be connected to the second selected reference object (source). When using Source-Target option, only the connected object is modified:

| source (modified) | target (unmodified) |

|

|

OmniMatch Types

OmniMatch supports the following match types:

| Match Type | Required Input | |

|---|---|---|

| First selection (target = object to be connected with shape modification) |

Second selection (source = reference object without shape modification) |

|

| Surface Edge | Surface Edge | |

| Surface Edge | Face Edge | |

| Surface Edge | Surface/Face Interior | |

| Surface Edge | Curve Interior | |

| Curve Endpoint | Curve Endpoint | |

| Curve Endpoint | Curve Interior | |

| Curve Endpoint | Surface Edge | |

| Curve Endpoint | Face Edge | |

| Curve Endpoint | Surface/Face Interior | |

Particular OmniMatch Parameters

- Mapping

- Only available for surface matching.

- (Modify) Orientation

- These options define whether only the connected object or both, connected and reference object are modified.

- Persistent Orientation

-

- Disable dynamic swapping

- Disables any dynamic swapping of Source-Target during control point modification.

- Swap

- Swaps connecting (target) and reference (source) edge or point, respectively.

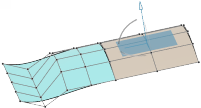

- Direction: X, Y, Z, View, Object, Auto

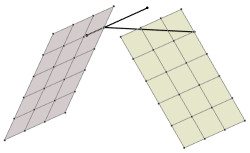

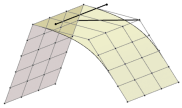

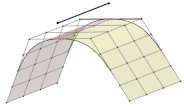

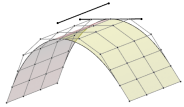

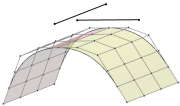

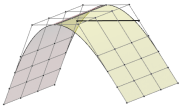

- Depending on the continuity, the target control points are moved when being matched to the source object. You can specify a direction to which the control point movement is fixed as far as this is possible in compliance with the continuity. This allows you to preserve the control points distribution in the normal plane of the selected direction axis.

- Direction

- Depending on the continuity, the target control points are moved when being matched to the source object. You can specify a direction to which the control point movement is fixed as far as this is possible in compliance with the continuity. This allows you to preserve the control points distribution in the normal plane of the selected direction axis.

- Automatic

- Computes the direction of the control point movement internally.

- Attach To View

- Sets the matching direction to the current view when the matching is recomputed, for example, after changing the continuity.

- Fix Direction

: X, Y, Z, View, Object, Auto

: X, Y, Z, View, Object, Auto - In the work area, the direction is represented by an OmniPlane handle that you can also manipulate to modify the direction dynamically.

- Automatic

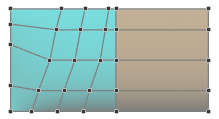

- Iso Curves

- Only available for surface matching.

- Tangent Ratio

- Only available for surface matching.

- Flow Control

- Only available for surface and curve to surface matching.

- Special

-

- Sliding

- In case of a T connection, you can move the curve end point along the curve or edge of the target object using the handle displayed in the work area.