Using Flow Control on Blend Surfaces | |||||

|

| ||||

-

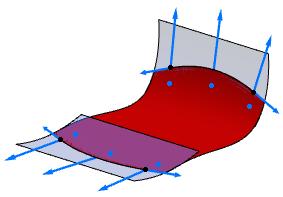

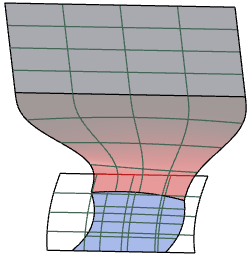

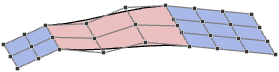

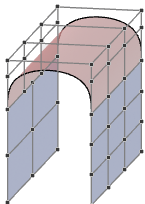

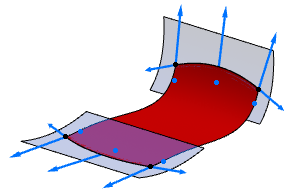

Create a blend surface from input surfaces as shown

below.

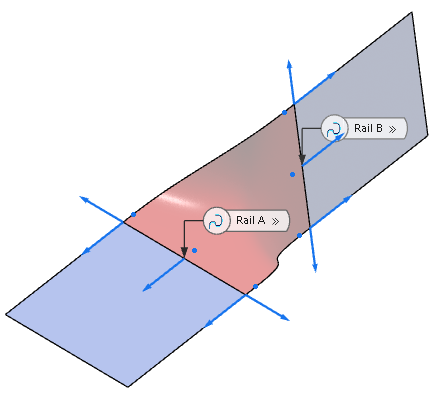

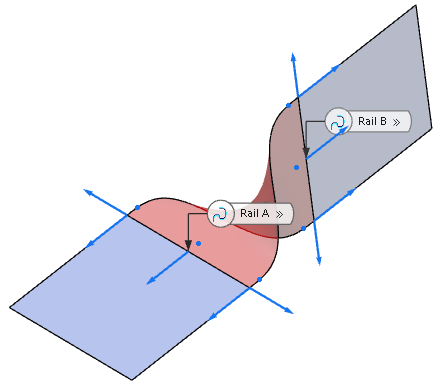

By default, the blend surface is created with the flow control option Free at Rail A and Rail B, that is the edge direction of the connecting edges of the blend surface is kept at the selected rail and rectified.

G1

G2 -

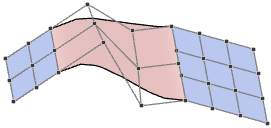

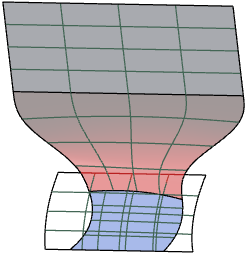

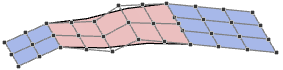

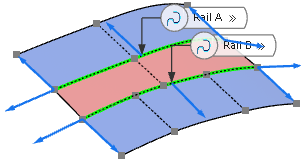

In the Flow Control section, select Linear

Align at Rail A and Rail

B.

The control point rows of the blend surface are aligned to the input surface at the selected rail.

G1

G2 - Select Edge Align.

-

Align a blend surface to a face.

-

Create a blend surface from a surface and a face created with the OmniCut

command.

command.

- Select All Edges.

-

Create a blend surface from a surface and a face created with the OmniCut

-

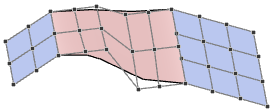

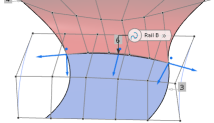

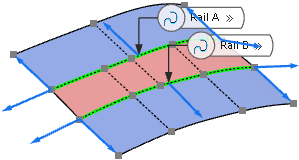

Change Edge Flow from Rail A to

Rail B.

The parameterization from the input surface is adopted at the selected edge.

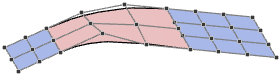

Parameterization from Rail A

Parameterization from Rail B -

Align the blend surface segmentation.

By default, the flow control aligns the segmentation of the blend surface with the selected rail. You can also align the segmentation with the other rail.

-

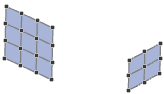

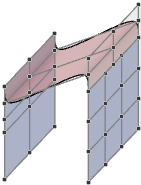

Open a 3D shape containing two joint surface clusters used as input geometry.

-

Create a blend surface and in the Geometry section of the OmniSurf panel, select Order V INP.

By default, the blend surface is created with a segmentation aligned with Rail A.

-

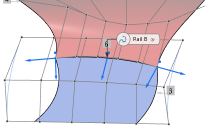

In the Edge Flow list, select Rail A+B.

The blend surface is created with a segmentation aligned with Rail B

-

Open a 3D shape containing two joint surface clusters used as input geometry.

-

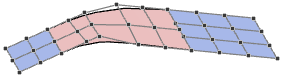

Select Reverse to reverse the direction of the blend

surface at the selected rail.

Original

Reverse Rail A -

Create a blend surface from two curves or surface edges with ambiguous orientation.

-

In the Flow Control section of the OmniSurf Parallel Curves panel, select Rev. Edge Dir.

The orientation of Rail B is reversed.

-

Create two surfaces with projected curves.

-

Create a blend surface from the curve projections.

-

Select the Extrapolation option

Both for Rail A and

Rail B to extrapolate the blend surface to the input

surface

edges.

If a blend surface is created from input curves projected onto a surface, you can extrapolate the edges of the created surface lying on the curves to the edges of the input surface. You can determine whether the edges shall be extrapolated at start or end of the guide curves or at both ends.

Note: The created surface can only be extrapolated if the rails can reach the support surface edges.