About Virtual Pins | |

| |

Examples of pins in assemblies include the hinged joint in laptop computers, pliers, and actuators. A virtual pin connection can be used when you only need to know the effects of a pin on its adjacent parts rather than the stress distribution on the pin itself. Creating a virtual pin connection is simpler and faster than applying contact between the pin and its contacting faces.

The virtual pin connection applies an underlying hinge restraint at each hole in the supports. The outer part is allowed to rotate freely about the cylindrical axis while the other five degrees of freedom are fixed.

Virtual pins include a torsional stiffness value to account for the resistance of motion in a hinge. The stiffness also accounts for the number of holes through which the pin passes. The following equation shows how the stiffness is distributed.

is the torsional stiffness, is the number of holes in support 1, is the number of holes in support 2, and is the effective stiffness at each hole.

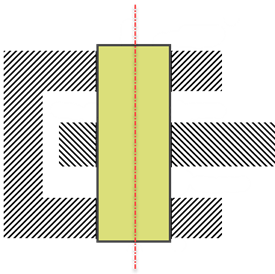

The following cutaway view shows two parts assembled with a pin. A virtual pin defined along the vertical centerline couples the virtual pin to each of the three holes.