About Smoothed Particle Hydrodynamics (SPH) | ||||

|

| |||

Finite elements are generally expected to remain attached to each other throughout a simulation. Particles can provide a more accurate solution in cases where the system undergoing analysis is expected to lose mass or otherwise separate during the simulation. Analyses such as fluid slosh problems (including waves breaking), bird strikes, and ballistic impacts are ideally suited to use of smoothed particles. The fluid or solid particles can separate from each other and either disperse or rejoin the main body to match the conditions of the real-world problem being simulated.

SPH in the 3DEXPERIENCE is a conversion process. You begin with a solid part definition and finite element mesh. You then convert the mesh to particles that retain the properties of the original solid. The SPH definition determines how the elements are converted; the particle size and material properties (mass, density, etc.) determine how the particles react in the simulation.

Two types of particle conversion are supported. You can define the particle conversion using a grid or using the original finite elements. Particles in a grid conversion are placed at the grid intersections. You can specify either uniform thickness (constant size), or variable thickness. The difference in thickness types is shown in the figure below.

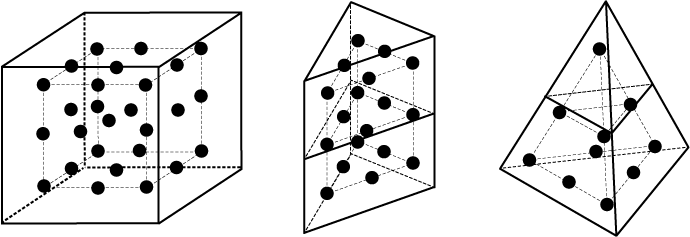

Conversion using the original finite elements creates equally spaced particles along the primary isoparametric element directions. You can choose the number of particles, from 1 to 7 that will be used. The image below shows how each type of element is converted using three elements per isoparametric direction.

Analyses involving finite element conversion to SPH particles are subject to the following limitations:

- Only reduced-integration continuum elements C3D8R, C3D6, and C3D4 are available for conversion.

- Surface loads specified on the faces of parent elements that convert during the analysis are not applied after conversion to particles. However, distributed loads like can be applied to other finite element surfaces that do not convert (such as those on a piston surface) that can apply a pressure onto the particle elements (such as the fluid pushed by the piston) using contact interactions.

- Bodies modeled with elements that might convert to particles that were not defined using the same section definition will not interact with each other between the converted portions of the bodies. For example, body A and body B allow elements to convert to particles, but these elements are associated with different section definitions. After conversion, the particles will not interact.

- Within a given body (part) defined with one solid section definition, gravity loads and mass scaling cannot be specified selectively on a subset of elements referenced by this definition. Instead, the two features must be applied to all the elements in the element set associated with the solid section definition.

- Progressive conversion of finite elements into SPH particles during an analysis (based on strain, stress, or a user-defined criterion) is supported only for serial SPH analyses, not for parallel SPH analyses.

- When element deletion is disabled, the tensile failure material cannot be used with plane stress, shell, membrane, beam, pipe, and truss elements.

- The tensile failure material without element deletion can be used only with plane strain, axisymmetric, and three-dimensional solid (continuum) elements.

- You cannot run an SPH analysis on multiple CPUs if the contact in your model is defined with specific surface pairs (inclusions).