Defining Line Fasteners Using the Support Boundary Method | |||||

|

| ||||

-

From

the Projection options, select one of the

following:

Option Description T Joint Defines a joint where the smallest angle between the supports is greater than 45 degrees. Lap Joint Defines a joint where the smallest angle between the supports is less than 45 degrees. -

Select the Penetration type to extend the mesh at the

intersection to fill the gap between the two supports.

Option Description None Does not create extra elements at the gap. Partial Creates elements to fill the gap between the supports, with duplicate nodes at the intersection. Full Creates elements to fill the gap between the supports, with shared nodes at the intersection. -

Select the appropriate Fillet type

(None, Single sided, or

Double sided (T joint only), as shown below).

- If you included fillets, enter Offset 1 and Offset 2, which are offsets from the intersection of the parts. In the above image, Offset 1 is in the vertical direction, and Offset 2 is in the horizontal direction.

- If you included fillets, enter the Fillet Thickness, which is the thickness of the shell section that represents the weld fillets.

-

Specify the Maximum projection distance, which defines

the maximum gap (distance) between the placement geometry and the body you are

connecting.

The fastener is not created if the placement geometry and the body are farther apart than this distance.

-

Specify the Maximum angle, which is the limit for the

angle of inclination between the two surfaces being fastened.

The app creates the fastener mesh even if the angle is exceeded. However, it issues a mesh warning.

- Optional:

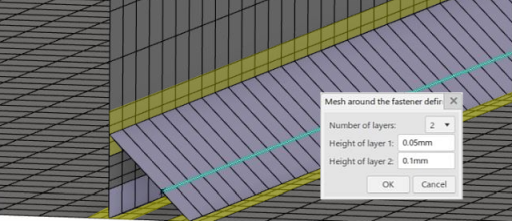

Do the following to define the Mesh around the fastener:

-

From the Realization options section of the

dialog box, click

to edit

the settings for the mesh around the projected weld curve.

to edit

the settings for the mesh around the projected weld curve.

- Specify the Number of Layersto surround the weld projection. You can specify between 0 and 4 layers.

- Specify the Height of layer 1 (layer 2, etc.), which defines the size of each of the layers surrounding the weld projection.

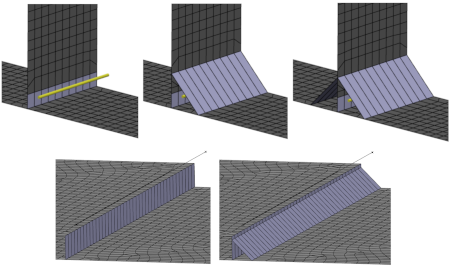

In the example below, the yellow highlights show the regions created by the mesh around the fastener settings.

-

From the Realization options section of the

dialog box, click

-

Select the Spacing defined by option to indicate the

method used to determine how many element edges are created along the projected

weld curves:

Option Description Mesh Size Uses the part mesh to determine the element size. Number of Edges Specifies the element size to accommodate the user-specified number of edges. Local Size Specifies the element size to a user-specified value input. - Specify the Number of layers to control the number of elements through the gap height or through the fillet face.

-

Set the Layer distribution to one of the

following:

Option Description Uniform Layers are the same height. Arithmetic Layers vary by a constant value. Geometric Layers vary by a constant ratio. - For multiple layers with nonuniform distribution, specify the Layer size ratio that controls the ratio of the largest to smallest layer size.

- Optional: Select Symmetric layers to make the layer distribution symmetrical.