-

From the

Compass,

click

Simulation

Apps

and select the

Structural Model Creation

app.

Each time you enter a model creation app, a new finite element model representation is created.

The Create Finite Element Model dialog box appears.

-

Choose which geometries will be initialized as supports of the mesh:

| Option | Description |

|---|

| Main body in each shape |

Initializes the main body only (that is, the PartBody). If the

PartBody is empty, the app initializes another solid body. If all solid bodies are empty, the

app initializes any ordered geometric set until there is a single 3D

result. |

| All geometries in all shapes |

Initializes all geometries of the part or assembly. |

| Select geometries |

Enables you to select which geometries of the part or assembly to

initialize for meshing. |

If you choose Select geometries, you can view a list of

imported geometries eligible for initialization by clicking Show

advanced tree selection to open the Body

selection dialog box. You can filter and select your geometries

from this dialog box.

Note:

In the case of ordered geometric sets, the app initializes all 2D and 3D geometries as supports. For more information,

see Ordered Geometric Sets in the Structural Model Creation Guide.

-

Choose the initialization method for the finite element model:

| Option | Description |

|---|

| None |

Creates a finite element model representation without creating a

mesh. Instead, you define the mesh parameters during the

creation process. This approach ensures that the created mesh is

suitable for your simulation. |

| Automatic |

Creates an initial mesh automatically according to the default mesh settings. For 2D

geometries, the app creates a surface quad mesh. For 3D geometries, the app creates a tetrahedron mesh. |

| Manual |

Creates an initial mesh based on your specifications for mesh type,

element order, size, and sag ratio. |

| Rule-based |

Creates an initial mesh based on a set of parameters in a meshing

rules document that you select. For more

information about meshing rules, see Creating and Modifying Meshing Rules. |

| Procedure-based |

Creates an initial mesh based on a set of initialization instructions in a Visual

Basic script. When you choose procedure-based initialization, you must

also define the inputs for the initialization script using a meshing

rules document. For more information about procedures, see About

User Procedures in the Model Assembly Design Guide. The status icon next to the Define

inputs button changes from red to green once you define

all the required inputs for the procedure. |

-

If you selected the Manual initialization method, you

must specify the following parameters:

-

Select the Mesh type.

-

Select the Element order, linear or

quadratic.

-

Specify the element Size.

The mesher might vary the element size to improve quality, conformance to geometry, or

other parameters.

-

If you selected Sweep 3D Mesh for solid

geometries, specify the Number of layers.

-

If you selected any other mesh type, specify the Sag

ratio.

The sag ratio controls the degree of conformance between the

mesh and curved geometry. It is the ratio of the maximum distance

between an element edge and the geometry to the length of the element

edge.

-

If your model includes surface geometries without a defined thickness,

specify the Thickness of the shell section.

-

Select Create knowledge parameters to create

Knowledgeware parameters.

- Optional:

To choose new mesh quality criteria, select the Select specific

quality criteria option and open a saved quality criteria file.

By default, the criteria specified in the options () are used.

-

Click OK.

You should always use the Mesh Creation

app to review the mesh. You can then edit the mesh or delete it and create a

new one that is suitable for your simulation.

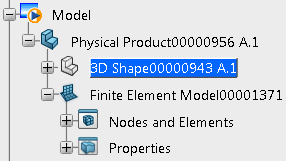

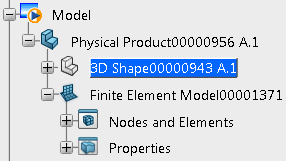

The FEM representation is created and displayed in the tree.

Finite Element Model00001371 contains two sets:

Nodes and Elements and Properties.

You can then create meshes (under the Nodes and Elements set)

while staying in your current modeling or scenario app;

for more information about creating meshes, see Meshing Geometries. To create meshes, you

must enter the Mesh Creation

app

to access the finite element representation tools.

To enter the Mesh Creation

app,

double-click the finite element model representation or an element belonging to the

finite element model representation: