Mold Tooling Design | |

| |

Mold Tooling Design provides the following work Flow with a Mold Project

| Roles | Command | ||

|---|---|---|---|

| 1 |  |

|

|

| 2 |  |

|

|

| 3 |  |

|

|

| 4 |  |

|

|

| 5 |  |

|

|

| 6 |  |

|

|

| 7 |  |

|

|

| 8 |

|

|

|

| 9 |

|

|

|

| 10 |

|

|

|

| 11 |

|

|

|

|

|

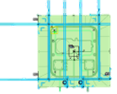

Another possible approach is working from a Mold Project:

- You create a Mold Project.

- You insert the design part in the Mold Project.

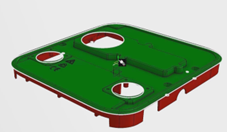

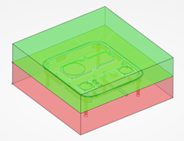

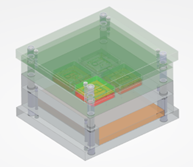

- Mold Tooling Design guides you through the conception of the Mold Base (Conceptual or detail design), as you create:

- Molded Part Publications

- An Insert Unit (Optional)

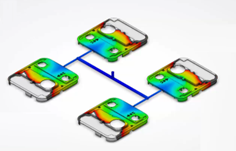

- A Multiple Layout Insert (Optional, applies only to multiprints)

- A Mold Base.

You can also work with a product structure you have created, used as template.

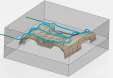

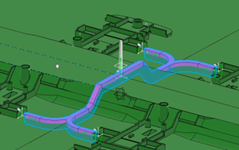

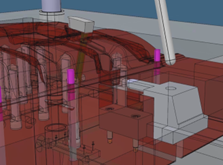

Mold Tooling Design can be considered as a tools box for mold makers. Use these tools to create Cooling Circuits and Runners and to place Components, Ejectors or Adaptive Systems.

Mold Tooling Design is a nativeapp available on the Cloud or on Premises.

For information on accessing Mold Tooling Design, see Opening an app from the Compass topic in the Getting Started User's Guide.