About Plastic Injection Molding | ||||

|

| |||

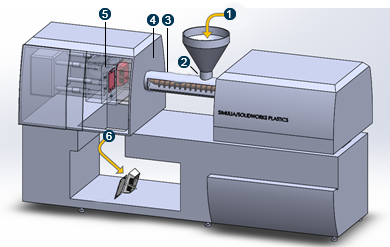

The image below illustrates the injection molding process from beginning to end. The numbered locations correspond to the different stages of the process. You can simulate stages 3 through 6 using the tools in the Plastic Injection app.

Plastic pellets enter the hopper.

Plastic pellets enter the hopper.

Pellets are heated to melting point in the barrel.

Pellets are heated to melting point in the barrel.

Fill simulation: Plastic injected by screw into mold cavity.

Fill simulation: Plastic injected by screw into mold cavity.

Pack simulation: Compensate for shrinkage and continue injecting material.

Pack simulation: Compensate for shrinkage and continue injecting material.

Mold simulation: Coolant is circulated through the mold to provide continuous cooling.

Mold simulation: Coolant is circulated through the mold to provide continuous cooling.

Ejection and warping: Mold is opened, part is ejected, and warpage or part deformation might

occur.

Ejection and warping: Mold is opened, part is ejected, and warpage or part deformation might

occur.