Composites Design | ||

| ||

Producibility Default Behavior

Specifies the default behavior of Producibility. This behavior can be modified in the Producibility dialog box, until plies are selected. Select the required option:

- Create a new producibility feature under each selected ply

- Modify the active producibility under each selected ply

![]() By default, Create a new

producibility feature under each selected ply is selected.

By default, Create a new

producibility feature under each selected ply is selected.

External Data Access

Select the required option:

- File-based system

- The default location to import or export Excel files is a file-based system one.

- Database

- The default location to import or export Excel files is a database one.

![]() By default, File-based system is

selected.

By default, File-based system is

selected.

Export Format

Select the required option:

- Excel (.xls)

- The default format to import or export Excel files is Excel (.xls).

- Extended Excel (.xlsx)

- The default format to import or export Excel files is Extended Excel (.xlsx).

- Text (txt - Not Recommended)

- The default format to import or export text files is .txt.

![]() By default, Excel (.xls) is

selected.

By default, Excel (.xls) is

selected.

Command Availability

- Disable non-applicable commands

- Disables non-applicable commands to improve the general

performance.

By default, Disable non-applicable

commands is selected.

By default, Disable non-applicable

commands is selected.

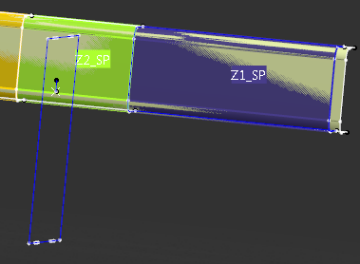

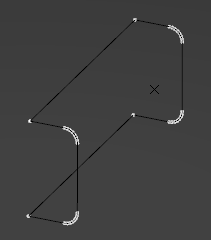

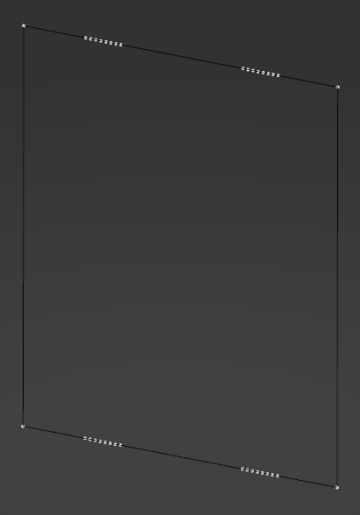

Ply Data Export

- Force generation of IGES 3D file whenever IGES 2D (flatten geometries) option is used

- Forces the export of data to IGES 3D format, even for

flatten 2D geometries that are normally exported to IGES 2D format. This option

impacts the behavior of

Ply Data Export. To illustrate the

explanations below, we have used a model like this one.

- When

Force generation of IGES 3D file whenever IGES 2D

(flatten geometries) option is used is cleared:

- When

IGES 3D (3D contours) is selected, 3D

contours of plies are exported to IGES 3D standard .igs format.

- When

IGES 2D (flatten geometries) is

selected, flatten geometries, if any, are exported to IGES 2D standard .ig2

format.

- When DXF (flatten geometries) is selected, flatten geometries, if any, are exported to DXF standard .dxf format.

- When

IGES 3D (3D contours) is selected, 3D

contours of plies are exported to IGES 3D standard .igs format.

- When

Force generation of IGES 3D file whenever IGES 2D

(flatten geometries) option is used is selected:

- When

IGES 2D (flatten geometries) is

selected, flatten geometries, if any, are exported to IGES 3D standard .igs

format.

- When

IGES 2D (flatten geometries) is

selected, flatten geometries, if any, are exported to IGES 3D standard .igs

format.

By default, Force generation of IGES 3D file

whenever IGES 2D (flatten geometries) option is used is not

selected.

By default, Force generation of IGES 3D file

whenever IGES 2D (flatten geometries) option is used is not

selected.

- When

Force generation of IGES 3D file whenever IGES 2D

(flatten geometries) option is used is cleared:

Grid and Virtual Stacking

Select required options:

- Display number of layers for all orientations thickness laws

- Display cell information in the Virtual Stacking table

![]() By default, Display number of layers for

all orientations thickness laws and Display cell information in

the Virtual Stacking table are not selected.

By default, Display number of layers for

all orientations thickness laws and Display cell information in

the Virtual Stacking table are not selected.

Additional Command Behaviors

- Signal overlapping plies (Grid approach)

- Displays alerts when

overlapping plies are found.

Signal overlapping plies (Grid approach) is selected.

Additional Display for Tree

Select required options:

- Show GridMask in tree on plies generated from Virtual Stacking management

- Those plies are linked to the virtual stacking and are re-synchronized

whenever the virtual stacking is updated.

By default, Show GridMask in tree on plies generated from

Virtual Stacking management is not selected.

By default, Show GridMask in tree on plies generated from

Virtual Stacking management is not selected.

- Show content of the preliminary design node in tree in the Manufacturing Stacking

- Provided the manufacturing stacking is created with all specs, you can

show content of the preliminary design node in the manufacturing

stacking. The content of the preliminary design can be extended

laminates and zones and transition zones.

By default, Show content of the preliminary design node in tree

in the Manufacturing Stacking is not selected.

By default, Show content of the preliminary design node in tree

in the Manufacturing Stacking is not selected.

Plies Group Consistency Check

- Enable draping direction and reference surface consistency checks on plies group update

- Whatever the status of this option, an inconsistency mask is displayed in the treeThe plies group is verified at update or edition.

- The diagnosis cannot be disabled in commands where inconsistent inputs lead to incorrect or unexpected results.

By default, Enable draping direction and reference surface consistency checks on plies group update is selected.

By default, Enable draping direction and reference surface consistency checks on plies group update is selected.

Ramp Specification

Select required options:

- Allow Centered Ramp Support (Not Recommended)

- When selected, gives access to the Centered Ramp Supports option when

specifying Ramp Definitions. It is not a recommended option, but it can be

useful in cases like legacy purpose.

When this option is selected, Ramp Definition proposes Centered Ramp Support in the Start options.

By default, Allow Centered Ramp

Support (Not Recommended) is not selected.

By default, Allow Centered Ramp

Support (Not Recommended) is not selected. - Show Ramp Definitions created by Grid Angle Cut

- Displays/Hides the Angle Cut Ramp Definitions node in the tree.

By default, Show

Ramp Definitions created by Grid Angle Cut is not

selected.

By default, Show

Ramp Definitions created by Grid Angle Cut is not

selected.

Data Review Information

Select Generate detailed information for review to add detailed information to the saved Composites model for review.

- Detailed information includes Rosettes, Ply Group/Sequence/Ply/Cut-Piece/Core, Core Samples, Section, and Stacking text attributes.

- The added information is visible in 3D Annotation Insight, without creating a 2D Ply book.

If the option is not selected, you need to generate a 2D Ply book to access the information.