Specifying Progressive Element Activation

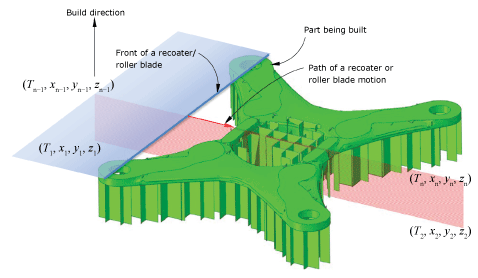

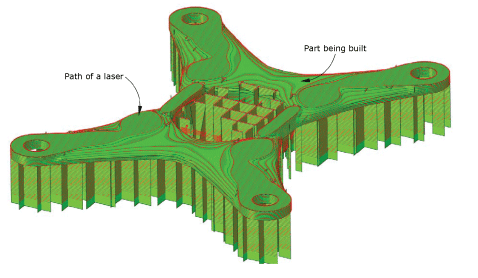

The layer-by-layer deposition of raw material from a recoater or roller blade is simulated using progressive element activation in a structural or a thermal analysis. The following steps are required to define the deposition process completely:

- Define the motion of the center point of the recoater in an event series following the convention for infinite line toolpath-mesh intersection (see Infinite Line Toolpath-Mesh Intersection).

- Create a table collection with a name that begins with "ABQ_AM". The table collection must contain a parameter table of type "ABQ_AM_MaterialDeposition".

- In the parameter table, include a reference to the event series for the material deposition, and set the deposition process type to "Roller".

- Refer to the table collection in the progressive element activation.

Abaqus activates elements automatically according to the specified material deposition sequence.

A dedicated collection of parameter table, property table, and event series types is available to include all of the definitions required by special-purpose techniques for additive manufacturing. You can use the abaqus fetch utility to obtain the file containing all of the type definitions of parameter tables, property tables, and event series required by the special-purpose techniques for additive manufacturing as follows:

abaqus fetch job=ABQ_am_special_purpose_types.inp