|

Define a Fatigue Crack Growth Analysis

The fatigue crack growth analysis capability in Abaqus/Standard is a quasi-static analysis on a structure subjected to subcritical cyclic loading. You

can use the fatigue crack growth procedure to simulate two different classes of problems

depending on the crack location.

At the brittle interface of laminated composites the cyclic loading leads to

interface strength degradation causing fatigue delamination growth. The onset

and growth of delamination are characterized by the fracture energy release

rate at the crack tip based on the Paris law (see

Paris, 1961).

The other class of problems is for brittle bulk materials, in which the

cyclic loading leads to material strength degradation causing fatigue crack

growth along an arbitrary path. Such an approach is based on the principles of

linear elastic fracture mechanics with the extended finite element method. The

onset and growth of the crack are also characterized by the fracture energy

release rate at the crack tip based on the Paris law (see

Paris, 1961).

If both failure mechanisms (that is, discrete fatigue crack growth in the bulk brittle material

and fatigue delamination growth at the brittle material interfaces) are considered within a

single analysis, the most critical failure mechanism governs the actual fatigue crack growth

and the damage in the region governed by the less critical failure mechanism is scaled

proportionally. In the vicinity where fracture or debonding occurs, linear elastic

deformation or the small scale yielding condition must be satisfied.

A fatigue crack growth analysis step can be the only step in an analysis,

can follow a general or linear perturbation step, or can be followed by a

general or linear perturbation step. Multiple fatigue crack growth analysis

steps can be included in a single analysis. The fatigue crack growth procedure

supports only constant amplitude loading—thermal, mechanical, or a combination

of thermal and mechanical. You must specify the cyclic loading amplitude curves

for a single loading cycle. Such a general formulation allows a wide range of

loading histories such as contact or complex combinations of asynchronous

loadings within a cyclic loading definition. For example, a mechanical pressure

and a temperature with peaks/troughs in each can occur at different times

within a single loading cycle.

The crack growth is governed by the Paris law:

where

and

are material constants.

For enriched elements, an equivalent form of the above Paris law based on the stress

intensity factor is also available:

Ratcliffe and Johnston (2014) and Deobald et al. (2017) proposed the following alternate

form of the fatigue law which better accounts for mixed-mode fatigue crack growth:

In the above expression,

is the total maximum strain energy release rate (as opposed to the strain

energy release rate change over a cycle used in the original form of the Paris law), while

and

are material parameters that depend on mode-mix and stress ratios. Abaqus does not support the above form of the crack growth rate equation directly, but instead

allows specification of

as a tabular function of

, the mode-mix ratio, and the stress ratio.

The details of the usages of the different fatigue crack growth models are discussed in

Fatigue Crack Growth Criterion for crack growth along initially partially bonded surfaces

and in Fatigue Crack Growth Criterion Based on the Principles of LEFM for crack growth in enriched elements.

In addition, a user-defined fatigue crack growth law can be specified in

user subroutine

UMIXMODEFATIGUE.

You specify the maximum numbers of cycles, ,

when you define the fatigue crack growth analysis step.

Simplifying the Fatigue Crack Growth Analysis

The general fatigue crack growth analysis procedure described above can be

simplified in some special cases if the following conditions are satisfied:

- the peak or the trough value of the strain energy release rate,

G, always occurs when the applied load,

P, reaches its maximum or minimum value;

- the strain energy release rate is proportional to the square of the

applied load, P; and

- the contact conditions remain unchanged during a single loading cycle.

For the simplified fatigue crack growth analysis, you can apply a constant load with a magnitude

of

(for the fracture energy release rate–based Paris law) or

(for the stress intensity factor–based Paris law), where

,

is the maximum applied load and

is the minimum applied load over a single cycle. At least two increments

are required for each single loading cycle period when the simplified method is used.

Controlling the Incrementation during the Cyclic Time Period

Several automatic incrementation methods are available. Alternatively, you

can use fixed time incrementation.

Automatic Incrementation

If you specify only the maximum allowable nodal temperature change in an

increment, the time increments are selected automatically based on this value.

Abaqus/Standard

restricts the time increments to ensure that the maximum temperature change is

not exceeded at any node during any increment of the analysis.

For rate-dependent constitutive equations you can limit the size of the

time increment by the accuracy of the integration. The user-specified accuracy

tolerance parameter limits the maximum inelastic strain rate change allowed

over an increment:

where

- t

- is the time at

the beginning of the increment,

- is the time increment (so that

is the time at the end of the increment), and

- is the equivalent creep strain

rate.

To achieve sufficient accuracy, the value chosen for the accuracy

tolerance parameter should be on the order of

for creep problems (where

is an acceptable level of error in the stress and E is a

typical elastic modulus) or on the order of the elastic strains for

viscoelasticity problems.

If rate-dependent constitutive equations are used in combination with a

varying temperature, both controls can be used simultaneously.

Abaqus/Standard

chooses the increments that satisfy both criteria.

If neither the accuracy tolerance parameter nor the maximum allowable

nodal temperature change is specified,

Abaqus/Standard

selects increment sizes based on computational efficiency.

Fixed Time Incrementation

If fixed time incrementation is preferred, you must specify the time

increment,

and the time period, T.

Defining the Time Points at Which the Response Must Be Evaluated

The user-defined time incrementation for a fatigue crack growth analysis

step can be augmented or superseded by specifying particular time points in the

loading history at which the response of the structure should be evaluated.

This feature is particularly useful if you know prior to the analysis at which

time points in the analysis the load reaches a maximum and/or minimum value or

when the response will change rapidly. An example is the analysis of the

heating/cooling thermal cycle of an engine component where you typically know

when the temperature reaches a maximum value.

When time points are used with fixed time incrementation, the time

incrementation specified for the fatigue crack growth step is ignored; instead,

the time incrementation precisely follows the specified time points. If time

points are used with automatic incrementation, the time incrementation is

variable; however, the response of the structure is evaluated at the specified

time points.

The time points can be listed individually, or they can be generated

automatically by specifying the starting time point, ending time point, and

increment in time between the two specified time points.

Discrete Crack Propagation along an Arbitrary Path with the Extended Finite Element Method

Fatigue crack growth analysis in

Abaqus/Standard

allows the modeling of discrete crack growth along an arbitrary path based on

the principles of linear elastic fracture mechanics with the extended finite

element method. You complete the definition of the crack propagation capability

by defining a fracture-based surface behavior and specifying the fracture

criterion in enriched elements. The fracture energy release rates at the crack

tips in enriched elements are calculated based on the modified virtual crack

closure technique (VCCT).

VCCT

uses the principles of linear elastic fracture mechanics. Therefore,

VCCT

is appropriate for problems in which brittle fatigue crack growth occurs,

although nonlinear material deformations can occur somewhere else in the bulk

materials. For more information about defining fracture criteria and

VCCT

in enriched elements, see

Modeling Discontinuities as an Enriched Feature Using the Extended Finite Element Method.

To accelerate the fatigue crack growth analysis, the damage extrapolation

technique is used, which advances the crack by at least one element length

after each completed cycle.

Onset and Growth of Fatigue Crack

The onset and growth of fatigue crack at an enriched element are

characterized by using the Paris law, which relates the relative fracture

energy release rate, ,

to crack growth rates. Two criteria must be met to initiate fatigue crack

growth:

- one criterion is based on material constants, ,

and the current cycle number, ;

- the other criterion is based on the maximum fracture energy release rate,

,

which corresponds to the cyclic energy release rate when the structure is

loaded up to its maximum value.

Once the onset of fatigue crack growth criterion is satisfied at the

enriched elements, the crack growth rate, ,

is a piecewise function based on a user-specified form of the Paris law. The

criteria for fatigue crack onset and growth are discussed in detail in

Modeling Discontinuities as an Enriched Feature Using the Extended Finite Element Method.

If you do not specify the onset criterion,

Abaqus/Standard

assumes that the onset of fatigue crack growth is satisfied automatically.

Progressive Delamination Growth along a Predefined Path at Interfaces

Fatigue crack growth analysis in

Abaqus/Standard

also allows the modeling of progressive delamination growth at the interfaces

in laminated composites. The interface along which the delamination (or crack)

propagates must be indicated in the model using a fracture criterion

definition. The fracture energy release rates at the crack tips in the

interface elements are calculated based on the virtual crack closure technique

(VCCT).

VCCT

uses the principles of linear elastic fracture mechanics. Therefore,

VCCT

is appropriate for problems in which brittle fatigue delamination growth occurs

along predefined surfaces, although nonlinear material deformations can occur

in the bulk materials. For more information about defining fracture criteria

and VCCT,

see

Crack Propagation Analysis.

To accelerate the fatigue crack growth analysis, the damage extrapolation

technique is used, which releases at least one element length at the crack tip

along the interface after each completed cycle. When both brittle fatigue

delamination at interfaces and discrete crack growth in bulk materials are

considered in an analysis, failure occurs first at the weakest link.

Onset and Growth of Fatigue Delamination

The onset and growth of fatigue delamination at a defined crack interface

are characterized by using the Paris law, which relates the relative fracture

energy release rate, ,

to crack growth rates. Two criteria must be met to initiate fatigue

delamination growth:

- one criterion is based on material constants, ,

and the current cycle number, ;

- the other criterion is based on the maximum fracture energy release rate,

,

which corresponds to the cyclic energy release rate when the structure is

loaded up to its maximum value.

Once the onset of the delamination growth criterion is satisfied at the

interface, the delamination growth rate, ,

is a piecewise function based on a user-specified form of the Paris law. The

criteria for fatigue delamination onset and growth are discussed in detail in

Fatigue Crack Growth Criterion.

If you do not specify the onset criterion,

Abaqus/Standard

assumes that the onset of fatigue crack growth is satisfied automatically.

Initial Conditions

Initial values of stresses, temperatures, field variables,

solution-dependent state variables, etc. can be specified (see

Initial Conditions).

Boundary Conditions

Boundary conditions can be applied to any of the displacement or rotation

degrees of freedom. During the analysis, prescribed boundary conditions in a

general fatigue crack growth step must have an amplitude definition that is

cyclic over the step: the start value must be equal to the end value (see

Amplitude Curves).

However, prescribed boundary conditions in a simplified fatigue crack growth

analysis must have a constant value. If the analysis consists of several steps,

the usual rules apply (see

Boundary Conditions).

At each new step the boundary condition can either be modified or completely

defined. All boundary conditions defined in previous steps remain unchanged

unless they are redefined.

Loads

The following loads can be prescribed in a fatigue crack growth analysis

step:

-

Concentrated nodal forces can be applied to the displacement degrees of

freedom (1–6); see

Concentrated Loads.

-

Distributed pressure forces or body forces can be applied; see

Distributed Loads.

The distributed load types available with particular elements are described in

the

Abaqus Elements Guide.

During the general fatigue crack growth analysis each load must have an

amplitude definition that is cyclic over the step where the start value must be

equal to the end value (see

Amplitude Curves).

However, each load must have a constant value in a simplified fatigue crack

growth analysis. If the analysis consists of several steps, the usual rules

apply (see

About Loads).

At each new step the loading can either be modified or completely defined. All

loads defined in previous steps remain unchanged unless they are redefined.

Predefined Fields

The following predefined fields can be specified in a fatigue crack growth

analysis step, as described in

Predefined Fields:

-

Temperature is not a degree of freedom in a fatigue crack growth analysis step, but nodal

temperatures can be specified as a predefined field. The temperature values specified in

a general fatigue crack growth analysis must be cyclic over the step: the start value

must be equal to the end value (see Amplitude Curves). If the

temperatures are read from the results file, you should specify initial temperature

conditions equal to the temperature values at the end of the step (see Initial Conditions).

Alternatively, you can ramp the temperatures back to their initial condition values, as

described in Predefined Fields. Any

difference between the applied and initial temperatures causes thermal strain if a

thermal expansion coefficient is given for the material (Thermal Expansion). The

specified temperature also affects temperature-dependent material properties, if any. In

a simplified fatigue crack growth analysis, the temperature values specified must be

constant.

-

The values of user-defined field variables can be specified. These

values affect only field-variable-dependent material properties, if any. The

field variable values specified in a general fatigue crack growth analysis must

be cyclic over the step. The field variable values must be constant in a

simplified fatigue crack growth analysis step.

Material Options

Most material models that describe mechanical behavior are available for use

in a fatigue crack growth analysis. The inelastic definition in a material

point must be used in conjunction with the linear elastic material model (Linear Elastic Behavior),

the porous elastic material model (Elastic Behavior of Porous Materials),

or the hypoelastic material model (Hypoelastic Behavior).

The following material properties are not active during a fatigue crack growth analysis: acoustic

properties, thermal properties (except for thermal expansion), mass diffusion properties,

electrical conductivity properties, piezoelectric properties, and pore fluid flow

properties.

Rate-dependent yield (Rate-Dependent Yield),

rate-dependent creep (Rate-Dependent Plasticity: Creep and Swelling),

and two-layer viscoplasticity (Two-Layer Viscoplasticity)

can also be used during a fatigue crack growth analysis.

However, in the vicinity where fracture or debonding occurs, linear elastic

deformation or the small scale yielding condition must be satisfied.

Elements

Any of the stress/displacement elements in Abaqus/Standard can be used in a fatigue crack growth analysis (see Choosing the Appropriate Element for an Analysis Type). However, when

modeling fatigue crack growth based on the principles of linear elastic fracture mechanics

with the extended finite element method, only first-order continuum stress/displacement

elements and second-order stress/displacement tetrahedral elements can be associated with an

enriched feature (see Modeling Discontinuities as an Enriched Feature Using the Extended Finite Element Method).

Output

In addition to the standard output identifiers available in

Abaqus

(Abaqus/Standard Output Variable Identifiers),

whole element and surface variables are available.

The following whole element variables are available with the extended finite

element method:

- STATUSXFEM

-

Status of the enriched element. (The status of an enriched element is 1.0 if

the element is completely cracked, 0.0 if the element is not. If the element is

partially cracked, the value lies between 1.0 and 0.0.)

- CYCLEINIXFEM

-

Number of cycles to initialize the crack at the enriched element.

- CYCLEXFEM

-

Number of cycles to fracture at the enriched element.

- ENRRTXFEM

-

All components of strain energy release rate.

The following

additional surface output variables can be also requested along a predefined

path at interfaces: - CSDMG

-

Overall value of the scalar damage variable.

- BDSTAT

-

Bond state. The bond state varies between 1.0 (fully bonded) and 0.0 (fully

unbonded).

- CYCLE

-

Number of cycles to debond.

- ENRRT

-

All components of strain energy release rate.

Limitations

The fatigue crack growth procedure supports only constant amplitude

loading—thermal, mechanical, or a combination of thermal and mechanical.

Several fatigue crack growth analysis steps can be used for an analysis with

variable amplitude loading with each step having a constant amplitude loading.

Significant inaccuracy in fatigue prediction can occur if the fatigue

procedure is used for cases that depart significantly from linear elastic

response near a crack. See

Low-Cycle Fatigue Analysis Using the Direct Cyclic Approach

for discussion of simulation fatigue crack growth involving ductile materials.

Input File Template

The

following is an example using the general fatigue crack growth analysis

procedure: HEADING

…

ENRICHMENT, TYPE=PROPAGATION CRACK, INTERACTION=INTERACTION,

ELSET=ENRICHED

BOUNDARY

Data lines to specify zero-valued boundary conditions

INITIAL CONDITIONS

Data lines to specify initial conditions

AMPLITUDE

Data lines to define amplitude variations

**

MATERIAL

Options to define material properties

SURFACE, INTERACTION=INTERACTION

SURFACE BEHAVIOR

FRACTURE CRITERION, TYPE=FATIGUE

Data lines to define material constants used in the Paris law and fracture criterion in the bulk

material for enriched elements

**

SURFACE, NAME=secondary

Data lines to define the secondary surface at the delamination interface

SURFACE, NAME=main

Data lines to define the main surface at the delamination interface

CONTACT PAIR

secondary, main

TIME POINTS, NAME=T1

**

STEP (,INC=)

Set INC equal to the maximum number of increments in a single loading cycle

FATIGUE, TYPE=CONSTANT AMPLITUDE, TIME POINTS=T1

Data line to define time increment, cycle time, minimum time increment allowed, and maximum time increment allowed

Data line to define minimum increment in number of cycles, maximum increment in number of cycles, total number of cycles, , tolerance for the least number of cycles to fracture

DEBOND, SECONDARY=secondary, MAIN=main

FRACTURE CRITERION, TYPE=FATIGUE

Data lines to define material constants used in the Paris law and fracture criterion at the interface

**

BOUNDARY, AMPLITUDE=

Data lines to prescribe zero-valued or nonzero boundary conditions

CLOAD and/or DLOAD, AMPLITUDE=

Data lines to specify loads

TEMPERATURE and/or FIELD, AMPLITUDE=

Data lines to specify values of predefined fields

**

END STEP The following is an example using the simplified fatigue

crack growth analysis procedure: HEADING

…

ENRICHMENT, TYPE=PROPAGATION CRACK, INTERACTION=INTERACTION,

ELSET=ENRICHED

BOUNDARY

Data lines to specify zero-valued boundary conditions

INITIAL CONDITIONS

Data lines to specify initial conditions

AMPLITUDE

Data lines to define a constant load equal to

**

MATERIAL

Options to define material properties

SURFACE, INTERACTION=INTERACTION

SURFACE BEHAVIOR

FRACTURE CRITERION, TYPE=FATIGUE

Data lines to define material constants used in the Paris law and fracture criterion in the bulk

material for enriched elements

**

SURFACE, NAME=secondary

Data lines to define the secondary surface at the delamination interface

SURFACE, NAME=main

Data lines to define the main surface at the delamination interface

CONTACT PAIR

secondary, main

TIME POINTS, NAME=T1

**

STEP (,INC=)

Set INC equal to the maximum number of increments in a single loading cycle (at least two increments are required)

FATIGUE, TYPE=SIMPLIFIED, TIME POINTS=T1

Data line to define time increment, cycle time, minimum time increment allowed, and maximum time increment allowed

Data line to define minimum increment in number of cycles, maximum increment in number of cycles, total number of cycles, , tolerance for the least number of cycles to fracture

DEBOND, SECONDARY=secondary, MAIN=main

FRACTURE CRITERION, TYPE=FATIGUE

Data lines to define material constants used in the Paris law and fracture criterion at the interface

**

BOUNDARY, AMPLITUDE=

Data lines to prescribe zero-valued or nonzero boundary conditions

CLOAD and/or DLOAD, AMPLITUDE=

Data lines to specify loads

TEMPERATURE and/or FIELD, AMPLITUDE=

Data lines to specify values of predefined fields

**

END STEP References

- Deobald, L.,

G. Mabson,

S. Engelstad,

M. Rao,

M. Gurvich,

W. Seneviratne,

S. Perera,

T. O'Brien,

G. Murri,

J. Ratcliffe,

C. Davila,

N. Carvalho

, and R. Krueger, “Guidelines

for VCCT-Based Interlaminar Fatigue and Progressive Failure Finite Element

Analysis,” NASA/TM-2017-219663, 2017.

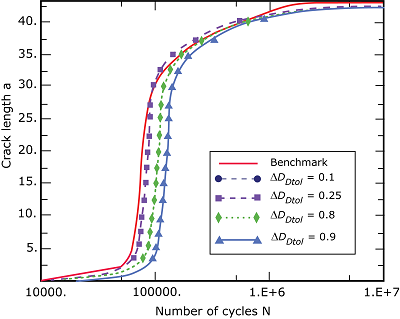

- Krueger, R., L. Deobald, and H. Gu, “A Benchmark Example for Delamination Growth Predictions Based on the Single Leg Bending Specimen under Fatigue Loading,” Advanced Modeling and Simulation in Engineering Sciences, vol. 7, no. 11, 2020.

- Paris, P.,

M. Gomaz

, and W. Anderson, “A

Rational Analytic Theory of Fatigue,” The

Trend in

Engineering, vol. 15, 1961.

- Ratcliffe, J., and W. Johnston,

“Influence of Mixed Mode I-Mode II Loading on

Fatigue Delamination Growth Characteristics of a Graphite Epoxy Tape

Laminate,” Proceedings of American Society

for Composites 29th Technical

Conference, 2014.

|