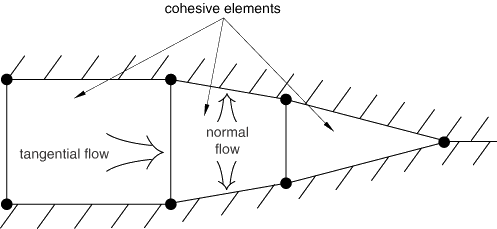

By default, there is no tangential flow of pore fluid within the cohesive

element. To allow tangential flow, define a gap flow property in conjunction

with the pore fluid material definition.

Newtonian Fluid

In the case of a Newtonian fluid the volume flow rate density vector is

given by the expression

where

is the tangential permeability (the resistance to the fluid flow),

is the pressure gradient along the cohesive element, and

is the gap opening.

In

Abaqus

the gap opening, ,

is defined as

where

and

are the current and original cohesive element geometrical thicknesses,

respectively; and

is the initial gap opening, which has a default value of 0.002.

Abaqus

defines the tangential permeability, or the resistance to flow, according to

Reynold's equation:

where

is the fluid viscosity and

is the gap opening. You can also specify an upper limit on the value of

.

Power Law Fluid

In the case of a power law fluid the constitutive relation is defined as

where

is the shear stress,

is the shear strain rate,

is the fluid consistency, and

is the power law coefficient.

Abaqus

defines the tangential volume flow rate density as

where

is the gap opening.

Bingham Plastic Fluid

In the case of a Bingham plastic fluid the volume flow rate density vector is given by the

expression

where

is the fluid consistency,

is the yield stress, and

is the gap opening. The unyielded fluid is modeled as a Newtonian

fluid with viscosity equal to

, where

has a default value of 107.

Herschel-Bulkley Fluid

In the case of a Herschel-Bulkley fluid the volume flow rate density vector is given by the

expression

where

is the fluid consistency,

is the power law coefficient,

is the yield stress, and

is the gap opening. The unyielded fluid is modeled as a Newtonian

fluid with viscosity equal to

, where

has a default value of 107.