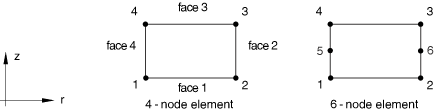

Element Types

General Element

- COHAX4

-

4-node cohesive element

Active Degrees of Freedom

1, 2 (, )

Additional Solution Variables

None.

Pore Pressure Elements

- CODAX4P(S)

-

6-node displacement and pore pressure cohesive element with the transition from Darcy flow to Poiseuille flow

- COHAX4P(S)

-

6-node displacement and pore pressure cohesive element

Active Degrees of Freedom

1, 2, 8

Additional Solution Variables

None.

Coupled Temperature-Displacement Element

- COHAX4T(S)

-

4-node displacement and temperature cohesive element

Active Degrees of Freedom

1, 2, 11

Additional Solution Variables

None.

Coupled Temperature-Pore Pressure Element

- CODAX4PT(S)

-

6-node temperature and pore pressure cohesive element

Active Degrees of Freedom

1, 2, 8,11 (1 and 2 on the middle face are constrained by corresponding values on the top and bottom faces)

Additional Solution Variables

None.