|

Element Types

Stress/Displacement Elements

- STRI3(S)

-

3-node triangular facet thin shell

- S3

-

3-node triangular general-purpose shell, finite membrane strains (identical

to element S3R)

- S3R

-

3-node triangular general-purpose shell, finite membrane strains (identical

to element S3)

- S3RS(E)

-

3-node triangular shell, small membrane strains

- STRI65(S)

-

6-node triangular thin shell, using five degrees of freedom per node

- S4

-

4-node general-purpose shell, finite membrane strains

- S4R

-

4-node general-purpose shell, reduced integration with hourglass control,

finite membrane strains

- S4RS(E)

-

4-node, reduced integration, shell with hourglass control, small membrane

strains

- S4RSW(E)

-

4-node, reduced integration, shell with hourglass control, small membrane

strains, warping considered in small-strain formulation

- S4R5(S)

-

4-node thin shell, reduced integration with hourglass control, using five

degrees of freedom per node

- S8R(S)

-

8-node doubly curved thick shell, reduced integration

- S8R5(S)

-

8-node doubly curved thin shell, reduced integration, using five degrees of

freedom per node

- S9R5(S)

-

9-node doubly curved thin shell, reduced integration, using five degrees of

freedom per node

Active Degrees of Freedom

1, 2, 3, 4, 5, 6 for STRI3, S3R, S3RS, S4, S4R, S4RS, S4RSW, S8R

1, 2, 3 and two in-surface rotations for STRI65, S4R5, S8R5, S9R5 at most nodes

1, 2, 3, 4, 5, 6 for STRI65, S4R5, S8R5, S9R5 at any node that

-

has a boundary condition on a rotational degree of freedom;

-

is involved in a multi-point constraint that uses rotational degrees of

freedom;

-

is attached to a beam or to a shell element that uses six degrees of

freedom at all nodes (such as S4R, S8R, STRI3, etc.);

-

is a point where different elements have different surface normals

(user-specified normal definitions or normal definitions created by

Abaqus

because the surface is folded); or

-

is loaded with moments.

Additional Solution Variables

Element type S8R5 has three displacement and two rotation variables at an

internally generated midbody node.

Heat Transfer Elements

- DS3(S)

-

3-node triangular shell

- DS4(S)

-

4-node quadrilateral shell

- DS6(S)

-

6-node triangular shell

- DS8(S)

-

8-node quadrilateral shell

Additional Solution Variables

None.

Coupled Temperature-Displacement Elements

- S3T(S)

-

3-node triangular general-purpose shell, finite membrane strains, bilinear

temperature in the shell surface (identical to element S3RT)

- S3RT

-

3-node triangular general-purpose shell, finite membrane strains, bilinear

temperature in the shell surface (for

Abaqus/Standard

it is identical to element S3T )

- S4T(S)

-

4-node general-purpose shell, finite membrane strains, bilinear temperature

in the shell surface

- S4RT

-

4-node general-purpose shell, reduced integration with hourglass control,

finite membrane strains, bilinear temperature in the shell surface

- S8RT(S)

-

8-node thick shell, biquadratic displacement, bilinear temperature in the

shell surface

Active Degrees of Freedom

1, 2, 3, 4, 5, 6 at all nodes

11, 12, 13, etc. (temperatures through the thickness as described in

Choosing a Shell Element)

at all nodes for S3T, S3RT, S4T, and S4RT; and at the corner nodes only for S8RT

Additional Solution Variables

None.

Nodal Coordinates Required

and, optionally for shells with displacement degrees of freedom in

Abaqus/Standard,

,

the direction cosines of the shell normal at the node.

Element Property Definition

Element-Based Loading

Distributed Loads

Distributed loads are available for all elements with displacement

degrees of freedom. They are specified as described in

Distributed Loads.

Body forces, centrifugal loads, and Coriolis forces must be given as

force per unit area if the equivalent section properties are specified directly

as part of the general shell section definition.

*dload

- Load ID (*DLOAD): BX

- FL−3

-

Body force (give magnitude as force per unit volume) in the global

X-direction.

- Load ID (*DLOAD): BY

- FL−3

-

Body force (give magnitude as force per unit volume) in the global

Y-direction.

- Load ID (*DLOAD): BZ

- FL−3

-

Body force (give magnitude as force per unit volume) in the global

Z-direction.

- Load ID (*DLOAD): BXNU

- FL−3

-

Nonuniform body force (give magnitude as force per unit volume) in the

global X-direction, with magnitude supplied via user

subroutine

DLOAD in

Abaqus/Standard

and

VDLOAD in

Abaqus/Explicit.

- Load ID (*DLOAD): BYNU

- FL−3

-

Nonuniform body force (give magnitude as force per unit volume) in the

global Y-direction, with magnitude supplied via user

subroutine

DLOAD in

Abaqus/Standard

and

VDLOAD in

Abaqus/Explicit.

- Load ID (*DLOAD): BZNU

- FL−3

-

Nonuniform body force (give magnitude as force per unit volume) in the

global Z-direction, with magnitude supplied via user

subroutine

DLOAD in

Abaqus/Standard

and

VDLOAD in

Abaqus/Explicit.

- Load ID (*DLOAD): CENT(S)

- FL−4

(ML−3T−2)

-

Centrifugal load (magnitude defined as ,

where

is the mass density and

is the angular speed).

- Load ID (*DLOAD): CENTRIF(S)

- T−2

-

Centrifugal load (magnitude is input as ,

where

is the angular speed).

- Load ID (*DLOAD): CORIO(S)

- FL−4T

(ML−3T−1)

-

Coriolis force (magnitude input ,

where

is the mass density and

is the angular speed). The load stiffness due to Coriolis loading is not

accounted for in direct steady-state dynamics analysis.

- Load ID (*DLOAD): EDLDn

- FL−1

-

General traction on edge n.

- Load ID (*DLOAD): EDLDnNU(S)

- FL−1

-

Nonuniform general traction on edge n with

magnitude and direction supplied via user subroutine

UTRACLOAD.

- Load ID (*DLOAD): EDMOMn

- F

-

Moment on edge n.

- Load ID (*DLOAD): EDMOMnNU(S)

- F

-

Nonuniform moment on edge n with magnitude

supplied via user subroutine

UTRACLOAD.

- Load ID (*DLOAD): EDNORn

- FL−1

-

Normal traction on edge n.

- Load ID (*DLOAD): EDNORnNU(S)

- FL−1

-

Nonuniform normal traction on edge n with

magnitude supplied via user subroutine

UTRACLOAD.

- Load ID (*DLOAD): EDSHRn

- FL−1

-

Shear traction on edge n.

- Load ID (*DLOAD): EDSHRnNU(S)

- FL−1

-

Nonuniform shear traction on edge n with

magnitude supplied via user subroutine

UTRACLOAD.

- Load ID (*DLOAD): EDTRAn

- FL−1

-

Transverse traction on edge n.

- Load ID (*DLOAD): EDTRAnNU(S)

- FL−1

-

Nonuniform transverse traction on edge n with

magnitude supplied via user subroutine

UTRACLOAD.

- Load ID (*DLOAD): GRAV

- LT−2

-

Gravity loading in a specified direction (magnitude is input as

acceleration).

- Load ID (*DLOAD): HP(S)

- FL−2

-

Hydrostatic pressure applied to the element reference surface and linear in

global Z. The pressure is positive in the direction of the

positive element normal.

- Load ID (*DLOAD): P

- FL−2

-

Pressure applied to the element reference surface. The pressure is positive

in the direction of the positive element normal.

- Load ID (*DLOAD): PNU

- FL−2

-

Nonuniform pressure applied to the element reference surface with magnitude

supplied via user subroutine

DLOAD in

Abaqus/Standard

and

VDLOAD in

Abaqus/Explicit.

The pressure is positive in the direction of the positive element normal.

- Load ID (*DLOAD): ROTA(S)

- T−2

-

Rotary acceleration load (magnitude is input as ,

where

is the rotary acceleration).

- Load ID (*DLOAD): ROTDYNF(S)

- T−1

-

Rotordynamic load (magnitude is input as ,

where

is the angular velocity).

- Load ID (*DLOAD): SBF(E)

- FL−5T

-

Stagnation body force in global X-,

Y-, and Z-directions.

- Load ID (*DLOAD): SP(E)

- FL−4T2

-

Stagnation pressure applied to the element reference surface.

- Load ID (*DLOAD): TRSHR

- FL−2

-

Shear traction on the element reference surface.

- Load ID (*DLOAD): TRSHRNU(S)

- FL−2

-

Nonuniform shear traction on the element reference surface with magnitude

and direction supplied via user subroutine

UTRACLOAD.

- Load ID (*DLOAD): TRVEC

- FL−2

-

General traction on the element reference surface.

- Load ID (*DLOAD): TRVECNU(S)

- FL−2

-

Nonuniform general traction on the element reference surface with magnitude

and direction supplied via user subroutine

UTRACLOAD.

- Load ID (*DLOAD): VBF(E)

- FL−4T

-

Viscous body force in global X-,

Y-, and Z-directions.

- Load ID (*DLOAD): VP(E)

- FL−3T

-

Viscous surface pressure. The viscous pressure is proportional to the

velocity normal to the element face and opposing the motion.

Foundations

Foundations are available for

Abaqus/Standard

elements with displacement degrees of freedom. They are specified as described

in

Element Foundations.

*foundation

- Load ID (*FOUNDATION): F(S)

- FL−3

-

Elastic foundation in the direction of the shell normal.

Distributed Heat Fluxes

Distributed heat fluxes are available for elements with temperature

degrees of freedom. They are specified as described in

Thermal Loads.

*dflux

- Load ID (*DFLUX): BF(S)

- JL−3 T−1

-

Body heat flux per unit volume.

- Load ID (*DFLUX): BFNU(S)

- JL−3 T−1

-

Nonuniform body heat flux per unit volume with magnitude supplied via user

subroutine

DFLUX.

- Load ID (*DFLUX):

MBFNU

(S)

-

JT−1

-

Nonuniform moving or stationary concentrated heat fluxes with magnitudes supplied

via user subroutine UMDFLUX.

- Load ID (*DFLUX): SNEG(S)

- JL−2 T−1

-

Surface heat flux per unit area into the bottom face of the element.

- Load ID (*DFLUX): SPOS(S)

- JL−2 T−1

-

Surface heat flux per unit area into the top face of the element.

- Load ID (*DFLUX): SNEGNU(S)

- JL−2

T−1

-

Nonuniform surface heat flux per unit area into the bottom face of the

element with magnitude supplied via user subroutine

DFLUX.

- Load ID (*DFLUX): SPOSNU(S)

- JL−2

T−1

-

Nonuniform surface heat flux per unit area into the top face of the element

with magnitude supplied via user subroutine

DFLUX.

Film Conditions

Film

conditions are available for elements with temperature degrees of freedom. They

are specified as described in

Thermal Loads.

*film

- Load ID (*FILM): FNEG(S)

- JL−2 T−1−1

-

Film coefficient and sink temperature (units of )

provided on the bottom face of the element.

- Load ID (*FILM): FPOS(S)

- JL−2 T−1−1

-

Film coefficient and sink temperature (units of )

provided on the top face of the element.

- Load ID (*FILM): FNEGNU(S)

- JL−2

T−1−1

-

Nonuniform film coefficient and sink temperature (units of

)

provided on the bottom face of the element with magnitude supplied via user

subroutine

FILM.

- Load ID (*FILM): FPOSNU(S)

- JL−2

T−1−1

-

Nonuniform film coefficient and sink temperature (units of

)

provided on the top face of the element with magnitude supplied via user

subroutine

FILM.

- Load ID (*FILM): FFS(S)

- JL−2 T−1−1

-

Film coefficient and sink temperature (units of )

provided on the top and bottom faces of the element.

- Load ID (*FILM): FFSNU(S)

- JL−2 T−1−1

-

Nonuniform film coefficient and sink temperature (units of

)

provided on the top and bottom faces of the element with magnitude supplied via

user subroutine.

Radiation Types

Radiation conditions are available for elements with temperature degrees

of freedom. They are specified as described in

Thermal Loads.

*radiate

- Load ID (*RADIATE): RNEG(S)

- Dimensionless

-

Emissivity and sink temperature (units of )

provided for the bottom face of the shell.

- Load ID (*RADIATE): RPOS(S)

- Dimensionless

-

Emissivity and sink temperature (units of )

provided for the top face of the shell.

- Load ID (*RADIATE): RFS(S)

- Dimensionless

-

Emissivity and sink temperature (units of )

provided for the top and bottom faces of the shell.

Surface-Based Loading

Distributed Loads

Surface-based distributed loads are available for all elements with

displacement degrees of freedom. They are specified as described in

Distributed Loads.

*dsload

- Load ID (*DSLOAD): EDLD

- FL−1

-

General traction on edge-based surface.

- Load ID (*DSLOAD): EDLDNU(S)

- FL−1

-

Nonuniform general traction on edge-based surface with magnitude and

direction supplied via user subroutine

UTRACLOAD.

- Load ID (*DSLOAD): EDMOM

- F

-

Moment on edge-based surface.

- Load ID (*DSLOAD): EDMOMNU(S)

- F

-

Nonuniform moment on edge-based surface with magnitude supplied via user

subroutine

UTRACLOAD.

- Load ID (*DSLOAD): EDNOR

- FL−1

-

Normal traction on edge-based surface.

- Load ID (*DSLOAD): EDNORNU(S)

- FL−1

-

Nonuniform normal traction on edge-based surface with magnitude supplied via

user subroutine

UTRACLOAD.

- Load ID (*DSLOAD): EDSHR

- FL−1

-

Shear traction on edge-based surface.

- Load ID (*DSLOAD): EDSHRNU(S)

- FL−1

-

Nonuniform shear traction on edge-based surface with magnitude supplied via

user subroutine

UTRACLOAD.

- Load ID (*DSLOAD): EDTRA

- FL−1

-

Transverse traction on edge-based surface.

- Load ID (*DSLOAD): EDTRANU(S)

- FL−1

-

Nonuniform transverse traction on edge-based surface with magnitude supplied

via user subroutine

UTRACLOAD.

- Load ID (*DSLOAD): HP(S)

- FL−2

-

Hydrostatic pressure on the element reference surface and linear in global

Z. The pressure is positive in the direction opposite to

the surface normal.

- Load ID (*DSLOAD): P

- FL−2

-

Pressure on the element reference surface. The pressure is positive in the

direction opposite to the surface normal.

- Load ID (*DSLOAD): PNU

- FL−2

-

Nonuniform pressure on the element reference surface with magnitude supplied

via user subroutine

DLOAD in

Abaqus/Standard

and

VDLOAD in

Abaqus/Explicit.

The pressure is positive in the direction opposite to the surface normal.

- Load ID (*DSLOAD): SP(E)

- FL−4T2

-

Stagnation pressure applied to the element reference surface.

- Load ID (*DSLOAD): TRSHR

- FL−2

-

Shear traction on the element reference surface.

- Load ID (*DSLOAD): TRSHRNU(S)

- FL−2

-

Nonuniform shear traction on the element reference surface with magnitude

and direction supplied via user subroutine

UTRACLOAD.

- Load ID (*DSLOAD): TRVEC

- FL−2

-

General traction on the element reference surface.

- Load ID (*DSLOAD): TRVECNU(S)

- FL−2

-

Nonuniform general traction on the element reference surface with magnitude

and direction supplied via user subroutine

UTRACLOAD.

- Load ID (*DSLOAD): VP(E)

- FL−3T

-

Viscous surface pressure. The viscous pressure is proportional to the

velocity normal to the element face and opposing the motion.

Distributed Heat Fluxes

Surface-based distributed heat fluxes are available for elements with

temperature degrees of freedom. They are specified as described in

Thermal Loads.

*dsflux

- Load ID (*DSFLUX): S(S)

- JL−2 T−1

-

Surface heat flux per unit area into the element surface.

- Load ID (*DSFLUX): SNU(S)

- JL−2 T−1

-

Nonuniform surface heat flux per unit area into the element surface with

magnitude supplied via user subroutine

DFLUX.

Film Conditions

Surface-based film conditions are available for elements with temperature

degrees of freedom. They are specified as described in

Thermal Loads.

*sfilm

- Load ID (*SFILM): F(S)

- JL−2 T−1−1

-

Film coefficient and sink temperature (units of )

provided on the element surface.

- Load ID (*SFILM): FNU(S)

- JL−2 T−1−1

-

Nonuniform film coefficient and sink temperature (units of

)

provided on the element surface with magnitude supplied via user subroutine

FILM.

Radiation Types

Surface-based radiation conditions are available for elements with

temperature degrees of freedom. They are specified as described in

Thermal Loads.

*sradiate

- Load ID (*SRADIATE): R(S)

- Dimensionless

-

Emissivity and sink temperature (units of )

provided for the element surface.

Incident Wave Loading

Element Output

If

a local coordinate system is not assigned to the element, the stress/strain

components, as well as the section forces/strains, are in the default

directions on the surface defined by the convention given in

Conventions.

If a local coordinate system is assigned to the element through the section

definition (Orientations),

the stress/strain components and the section forces/strains are in the surface

directions defined by the local coordinate system. In

large-displacement problems with elements that allow finite membrane strains in

Abaqus/Standard

and in all problems in

Abaqus/Explicit,

the local directions defined in the reference configuration are rotated into

the current configuration by the average material

rotation.

Stress, Strain, and Other Tensor Components

Stress and other tensors (including strain tensors) are available for

elements with displacement degrees of freedom. All tensors have the same

components. For example, the stress components are as follows:

- S11

-

Local

direct stress.

- S22

-

Local

direct stress.

- S12

-

Local

shear stress.

Section Forces, Moments, and Transverse Shear Forces

Available for elements with displacement degrees of freedom.

- SF1

-

Direct membrane force per unit width in local 1-direction.

- SF2

-

Direct membrane force per unit width in local 2-direction.

- SF3

-

Shear membrane force per unit width in local 1–2 plane.

- SF4

-

Transverse shear force per unit width in local 1-direction (available only

for S3/S3R, S3RS, S4, S4R, S4RS, S4RSW, S8R, and S8RT).

- SF5

-

Transverse shear force per unit width in local 2-direction (available only

for S3/S3R, S3RS, S4, S4R, S4RS, S4RSW, S8R, and S8RT).

- SM1

-

Bending moment force per unit width about local 2-axis.

- SM2

-

Bending moment force per unit width about local 1-axis.

- SM3

-

Twisting moment force per unit width in local 1–2 plane.

The section force and moment resultants per unit length in the normal basis

directions in a given shell section of thickness h can be

defined on this basis as

where

is the offset of the reference surface from the midsurface.

The section force SF6, which is the integral of

through the shell thickness, is reported only for finite-strain shell elements

and is zero because of the plane stress constitutive assumption. The total

number of attributes written to the results file for finite-strain shell

elements is 9; SF6 is the sixth attribute.

Average Section Stresses

Available for elements with displacement degrees of freedom.

- SSAVG1

-

Average membrane stress in local 1-direction.

- SSAVG2

-

Average membrane stress in local 2-direction.

- SSAVG3

-

Average membrane stress in local 1–2 plane.

- SSAVG4

-

Average transverse shear stress in local 1-direction.

- SSAVG5

-

Average transverse shear stress in local 2-direction.

The average section stresses are defined as

where h is the current section thickness.

Section Strains, Curvatures, and Transverse Shear Strains

Available for elements with displacement degrees of freedom.

- SE1

-

Direct membrane strain in local 1-direction.

- SE2

-

Direct membrane strain in local 2-direction.

- SE3

-

Shear membrane strain in local 1–2 plane.

- SE4

-

Transverse shear strain in the local 1-direction (available only for S3/S3R, S3RS, S4, S4R, S4RS, S4RSW, S8R, and S8RT).

- SE5

-

Transverse shear strain in the local 2-direction (available only for S3/S3R, S3RS, S4, S4R, S4RS, S4RSW, S8R, and S8RT).

- SE6

-

Strain in the thickness direction (available only for S3/S3R, S3RS, S4, S4R, S4RS, and S4RSW).

- SK1

-

Curvature change about local 2-axis.

- SK2

-

Curvature change about local 1-axis.

- SK3

-

Surface twist in local 1–2 plane.

The local directions are defined in

About Shell Elements.

Shell Thickness

- STH

-

Shell thickness, which is the current section thickness for S3/S3R, S3RS, S4, S4R, S4RS, and S4RSW elements.

Transverse Shear Stress Estimates

Available for S3/S3R, S3RS, S4, S4R, S4RS, S4RSW, S8R, and S8RT elements. - TSHR13

-

13-component of transverse shear stress.

- TSHR23

-

23-component of transverse shear stress.

Estimates of the transverse shear stresses are available at section

integration points as output variables TSHR13 or TSHR23 for both Simpson's rule and Gauss quadrature. For Simpson's

rule output of variables TSHR13 or TSHR23 should be requested at nondefault section points, since the

default output is at section point 1 of the shell section where the transverse

shear stresses vanish. For the small-strain elements in

Abaqus/Explicit,

transverse shear stress distributions are assumed constant for non-composite

sections and piecewise constant for composite sections; therefore, transverse

shear stresses at integration points should be interpreted accordingly.

For element type S4 the transverse shear calculation is performed at the center of

the element and assumed constant over the element. Hence, transverse shear

strain, force, and stress will not vary over the area of the element.

For numerically integrated shell sections (with the exception of

small-strain shells in

Abaqus/Explicit),

estimates of the interlaminar shear stresses in composite sections—i.e., the

transverse shear stresses at the interface between two composite layers—can be

obtained only by using Simpson's rule. With Gauss quadrature no section

integration point exists at the interface between composite layers.

Unlike the S11, S22, and S12 in-plane stress components, transverse shear stress components TSHR13 and TSHR23 are not calculated from the constitutive behavior at points

through the shell section. They are estimated by matching the elastic strain

energy associated with shear deformation of the shell section with that based

on piecewise quadratic variation of the transverse shear stress across the

section, under conditions of bending about one axis (see

Transverse shear stiffness in composite shells and offsets from the midsurface).

Therefore, interlaminar shear stress calculation is supported only when each

layer of the shell section is defined using an elastic material model or a

user-defined material model with the elastic transverse shear moduli defined.

If you specify the transverse shear stiffness values, interlaminar shear stress

output is not available.

Heat Flux Components

Available for elements with temperature degrees of freedom.

- HFL1

-

Heat flux in local 1-direction.

- HFL2

-

Heat flux in local 2-direction.

- HFL3

-

Heat flux in local 3-direction.

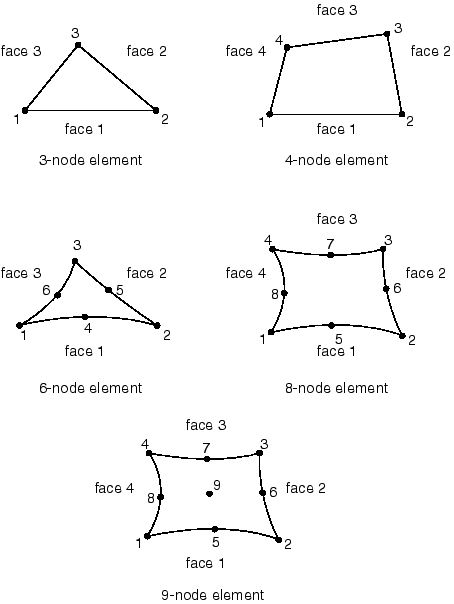

Node Ordering on Elements

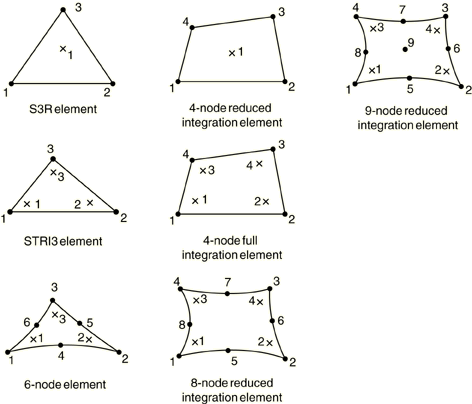

Numbering of Integration Points for Output

Stress/Displacement Analysis

Heat Transfer Analysis

|