Accounting for Shell and Membrane Thickness

All of the contact formulations except the finite-sliding, node-to-surface formulation account for initial shell and membrane thicknesses for element-based surfaces by default. The finite-sliding, node-to-surface formulation will not account for surface thickness. Node-based surfaces have no thickness, regardless of which element types are connected to the surface nodes. Accounting for element thicknesses in contact calculations is generally desirable, but you can avoid having thickness considered if it is not desired.

Example

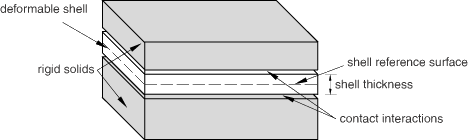

Consider the case of a shell pinched between two rigid surfaces, as shown in Figure 1.

In this example contact pairs using the small-sliding, node-to-surface formulation are defined between the top surface of the shell and the top rigid surface and between the bottom surface of the shell and the bottom rigid surface. Although the shell surfaces are defined at the shell reference location, the contact interactions account for the thickness of the shell and are offset from the reference surface. The penalty constraint enforcement method (see Contact Pressure-Overclosure Relationships) is used to avoid overconstraining secondary nodes. The following input is used:

SURFACE, NAME=TOP_RIG_SURF TOP_RIG_ELS, SURFACE, NAME=SHELL_TOP_SURF SHELL_ELS,SPOS SURFACE, NAME=SHELL_BOT_SURF SHELL_ELS,SNEG SURFACE, NAME=BOT_RIG_SURF BOT_RIG_ELS, CONTACT PAIR, INTERACTION=INTER_AL, SMALL SLIDING SHELL_TOP_SURF, TOP_RIG_SURF SHELL_BOT_SURF, BOT_RIG_SURF SURFACE INTERACTION, NAME=INTER_AL SURFACE BEHAVIOR, PENALTY