Adjustments of Overclosed Surfaces in the First Step of the Simulation

Abaqus/Explicit will automatically adjust the positions of surfaces to remove any initial overclosures that exist when a contact pair is defined in the first step of a simulation, except when nodes of a rigid body act as a secondary nodes or user subroutine VUINTER is used*CLEARANCE. The adjustments are made with strain-free initial displacements to the secondary nodes on the surfaces. Therefore, when a balanced main-secondary contact pair is defined, nodes on both surfaces may be adjusted. This automatic adjustment of surface position is intended to correct only minor mismatches associated with mesh generation. You can review the surface adjustments in the status (.sta) file, the message (.msg) file, and the output database (.odb) file; see Contact Diagnostics in an Abaqus/Explicit Analysis for more information.

Some softened contact models have nonzero contact pressure at zero overclosure (see Contact Pressure-Overclosure Relationships). For these models some initial, nonequilibrated contact pressure may be present at the beginning of an analysis, as the adjustments are made to satisfy zero overclosure rather than zero contact pressure. Large initial contact pressures may cause excessive distortion of elements near the contact surfaces.

Conflicting adjustments from separate contact pairs will cause incomplete resolution of initial overclosures and will lead to a noisy solution or severe distortion of elements. This can occur when a secondary node is pinched between two main surfaces.

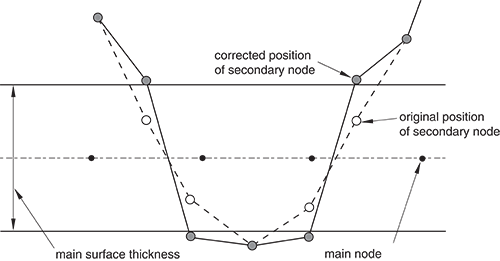

Because of the lack of a unique outward direction from double-sided facets, the resolution of large initial penetrations for double-sided surfaces can be difficult. Initial penetration will be detected only when a secondary node lies within the thickness of the underlying element, and the initial penetration will be resolved by moving the secondary node to the nearest free surface as shown in Figure 1.

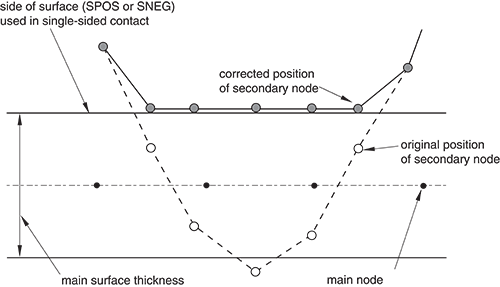

A warning message will be issued to the status (.sta) file if two adjacent secondary nodes (connected by a facet edge) are detected on opposite sides of a double-sided main surface involved in contact defined with the contact pair algorithm. No such warning will be issued for node-based surface nodes on opposite sides of a double-sided main surface, because adjacency cannot be determined among the node-based surface nodes. If the main surface is a single-sided surface, initial overclosures will be resolved using the surface normal of the main surface, as shown in Figure 2.

Having secondary nodes trapped on opposite sides of a double-sided main surface will often lead to serious problems, which may not became apparent until later in an analysis. Therefore, a data check analysis (see Abaqus/Standard and Abaqus/Explicit Execution) is recommended prior to running a large contact pair analysis so that you can check for warning messages in the status file (.sta) and check for mislocated adjacent secondary nodes on opposite sides of the main surface.

The adjustments affect only the nodes on the surfaces. Excessive distortion of neighboring elements may result if this feature is used to correct for gross errors in the initial geometry, causing the analysis to end with an error message.

Nodes on a rigid body can act as secondary nodes only for penalty contact pairs. Initial penetrations of secondary nodes that are part of a rigid body are not resolved with strain-free corrections; i.e., the secondary nodes are not adjusted. These penetrations are likely to cause artificially large contact forces in the first increments of an analysis and should, therefore, be avoided in the mesh definition.