Defining the Modified Elastic Behavior

The modified elastic behavior is obtained by first solving for the principal stresses assuming linear elasticity and then setting the appropriate principal stress values to zero. The associated stiffness matrix components will also be set to zero. These models are not history dependent: the directions in which the principal stresses are set to zero are recalculated at every iteration.

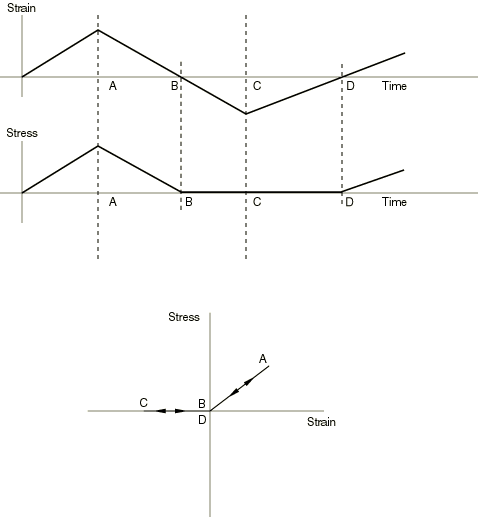

The no compression effect for a one-dimensional stress case such as a truss or a layer of a beam in a plane is illustrated in Figure 1. No compression and no tension definitions modify only the elastic response of the material.