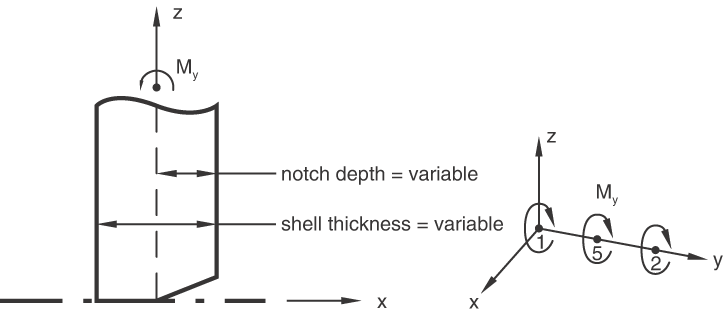

LS3S with constant-depth notch under far-field bending

Problem description

ELEMENT, TYPE=LS3S, ELSET=ALL

1, 2, 5, 1

SURFACE FLAW, SIDE=POSITIVE

1, .05

5, .05

2, .05

SHELL SECTION, MAT=M1, ELSET=ALL

.1,

Material:

Linear elastic, Young's modulus = 1.0, Poisson's ratio = 0.0. Boundary conditions:

0 at nodes 1, 2, and 5. Loading:

M −1.0 at nodes 1 and 2. M −4.0 at node 5. Results and discussion

| Element | Pt. | J | K | Jelastic | Jplastic |

|---|

| 1 |

1 |

4.43 × 106 |

2105.0 |

4.43 × 106 |

0.0 |

| 1 |

2 |

4.43 × 106 |

2105.0 |

4.43 × 106 |

0.0 |

| 1 |

3 |

4.43 × 106 |

2105.0 |

4.43 × 106 |

0.0 |

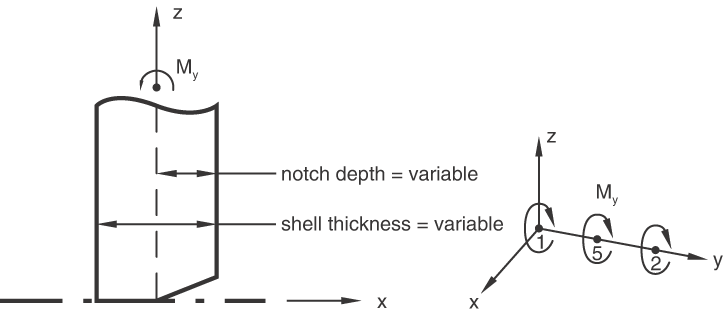

LS3S with variable depth notch under far-field bending

Problem description

ELEMENT, TYPE=LS3S, ELSET=ALL

1, 2, 5, 1

SURFACE FLAW, SIDE=POSITIVE

1, .07

5, .05

2, .04

SHELL SECTION, MAT=M1, ELSET=ALL, NODAL THICKNESS

99,

NODAL THICKNESS

1, 0.7

5, 0.5

2, 0.4

3, 0.1

4, 0.1

6, 0.1

7, 0.1

8, 0.1

Material:

Linear elastic, Young's modulus = 1.0, Poisson's ratio = 0.0. Boundary conditions:

0 at nodes 1, 2, and 5. Loading:

M −1.0 at nodes 1 and 2. M −4.0 at node 5. Results and discussion

| Element | Pt. | J | K | Jelastic | Jplastic |

|---|

| 1 |

1 |

6891.0 |

83.012 |

6891.0 |

0.0 |

| 1 |

2 |

3528.5 |

59.401 |

3528.5 |

0.0 |

| 1 |

3 |

1286.2 |

35.864 |

1286.2 |

0.0 |

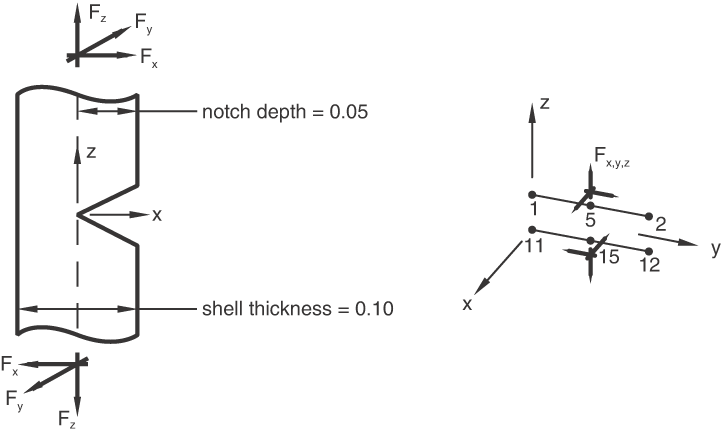

LS6 under far-field bending

Problem description

ELEMENT, TYPE=LS6, ELSET=ALL

1, 2, 5, 1, 12, 15, 11

SURFACE FLAW, SIDE=POSITIVE

1, .05

5, .05

2, .05

SHELL SECTION, MAT=M1, ELSET=ALL

.1,

Material:

Linear elastic, Young's modulus = 1.0, Poisson's ratio = 0.0. Boundary conditions:

Node 17 is fully constrained. 0 for all nodes. Nodes 1, 2, and 5 are constrained to move together. Nodes 11, 12, and 15 are constrained to move together. Loading:

M −6.0 at node 5. M 6.0 at node 15. Results and discussion

| Element | Pt. | J | Jelastic | Jplastic | KI | KII | KIII |

|---|

| 1 |

1 |

4.43 × 106 |

4.43 × 106 |

0.0 |

2105.0 |

0.0 |

0.0 |

| 1 |

2 |

4.43 × 106 |

4.43 × 106 |

0.0 |

2105.0 |

0.0 |

0.0 |

| 1 |

3 |

4.43 × 106 |

4.43 × 106 |

0.0 |

2105.0 |

0.0 |

0.0 |

LS3S under far-field tension

Problem description

ELEMENT, TYPE=LS3S, ELSET=ALL

1, 2, 5, 1

SURFACE FLAW, SIDE=POSITIVE

1, .05

5, .05

2, .05

SHELL SECTION, MAT=M1, ELSET=ALL

.1,

Material:

Linear elastic, Young's modulus = 1.0, Poisson's ratio = 0.0. Boundary conditions:

0 at nodes 1, 2, and 5. Loading:

F 1.0 at nodes 3 and 4. F 4.0 at node 7. Results and discussion

| Element | Pt. | J | K | Jelastic | Jplastic |

|---|

| 1 |

1 |

4518.0 |

67.22 |

4518.0 |

0.0 |

| 1 |

2 |

4518.0 |

67.22 |

4518.0 |

0.0 |

| 1 |

3 |

4518.0 |

67.22 |

4518.0 |

0.0 |

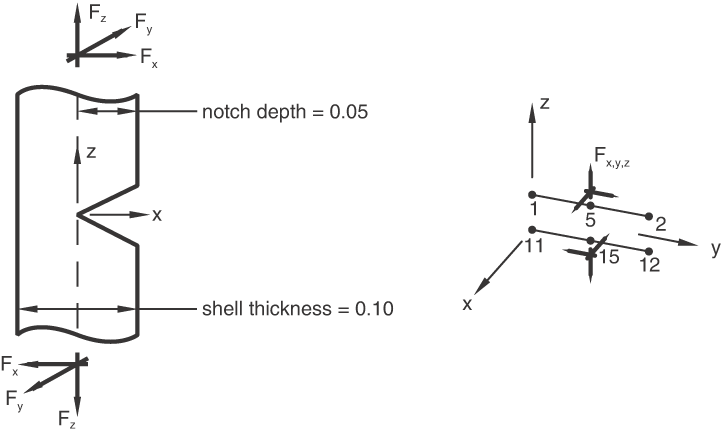

LS6 under Mode I, II, and III loading

Problem description

ELEMENT, TYPE=LS6, ELSET=ALL

1, 2, 5, 1, 12, 15, 11

SURFACE FLAW, SIDE=POSITIVE

1, .05

5, .05

2, .05

SHELL SECTION, MAT=M1, ELSET=ALL

.1,

Material:

Linear elastic, Young's modulus = 1.0, Poisson's ratio = 0.0. Boundary conditions:

Node 17 is fully constrained. 0 for all nodes. Nodes 1, 2, and 5 are constrained to move together. Nodes 11, 12, and 15 are constrained to move together. Loading:

1.0 at node 5. −1.0 at node 15. Results and discussion

| Element | Pt. | J | Jelastic | Jplastic | KI | KII | KIII |

|---|

| 1 |

1 |

170.10 |

170.10 |

0.0 |

11.20 |

4.962 |

−4.472 |

| 1 |

2 |

170.10 |

170.10 |

0.0 |

11.20 |

4.962 |

−4.472 |

| 1 |

3 |

170.10 |

170.10 |

0.0 |

11.20 |

4.962 |

−4.472 |

|