Manage Attributes on the Fastener Reference

-

Locate the Fastening

app

standard file (Fst_Standard.xls).

-

Edit the standard file as follows:

-

Add the "Structure" category in the "FTYP_CLASSATTRCATEGORIES" row.

-

Insert a new row, "FTYP_CLASSATTRLIST_Structure", and define attributes in it,

for example, the "Joint" attribute.

-

Edit the excel file of the required process type, MIG, for

example.

-

Add the attributes in the "Fst_CLASSATTRLIST" row.

-

Insert new rows for specifying the values of the attributes. For example, insert

a "Fst_CLASSATTR_Joint" row for the "Joint" attribute and specify its value.

For more information about customizing the fastener standard files, see

Fastening User's Guide: Administration: Working with the Fastener Standard and

Reference Fastener Type Files.

Create a Fastener Reference

-

Create a unified bead fastener reference.

-

Select

-

In the New Content panel, expand

Fasteners and select Unified Bead

Fastener

. .

-

Create a physical product with a 3D shape and switch to the Fastening

app.

-

Instantiate the unified bead fastener reference under the physical product with the

Explicit Mode

location

option, using the Fastener Instantiation location

option, using the Fastener Instantiation

command. For more

information, see Fastening User's Guide: Instantiating Fasteners: Instantiating Bead Fasteners and Unified

Bead Fasteners. command. For more

information, see Fastening User's Guide: Instantiating Fasteners: Instantiating Bead Fasteners and Unified

Bead Fasteners.

-

Right-click the unified bead fastener's node in the tree, select Properties, and click Reset instance

position to identity

in

the Position tab. in

the Position tab.

Create the Fastener Geometry

-

In the fastener reference, create a parameter and name it 'Reference'.

This parameter is used to recognize the original fastener reference. During

generation of the fastener, the value of this parameter is assigned automatically from

the value of the "ResourceIdentifier" keyword in a catalog or classification attribute

in a library.

-

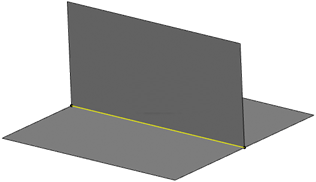

Under a geometrical set, create two surfaces as shown below to represent a dummy

pilot and joined part geometry.

-

Define input geometry.

Create input features. The input features are replaced with the computed geometries

of the pilot and joined parts. There are two methods to replace the input

features:

- Replace the input features with the automatically computed geometry.

- Replace the input features with the named geometry, using key names.

Notes:

- The input features must be aggregated under a geometrical set named

"Input".

- The features must be of the multiple extract type.

- Input features must respect the following naming convention: (Object

Type)_Input_(Numbering)_(Geometry Type)_(Usage)

- Object Type: Plate or Profile

- Geometry Type: Face, Edge, ResultFace, or ResultEdge

- Usage:

-

Define a result geometry for the fastener curve.

- For the computed geometry, create an interference feature between the input

features.

- For the named geometry, define a curve as required from the input features.

-

Edit the unified bead fastener reference and change the location option to

On Curve Mode

and select the

curve. and select the

curve.

-

Edit the engineering connection of the fastener.

-

Remove the RollCurve type constraints

-

Set the constraints type to User Defined.

-

Isolate the unified bead reference from the product using the Links and

Relations command.

|

> Preferences > App Preferences > 3D Modeling > Multi Discipline Engineering

> Fastening > General > Standard Management to find the location of the standard file.

> Preferences > App Preferences > 3D Modeling > Multi Discipline Engineering

> Fastening > General > Standard Management to find the location of the standard file. in

the

in

the