-

From the

Operation section of the

action bar,

click

Seam

.

The Seam dialog box appears.

.

The Seam dialog box appears. - In the Panel box, select a panel.

-

In the

Splitting Object box, select an object to

split the panel.

You can select any number of splitting objects. The splitting object can be a plane, a curve, a surface, or another panel. The splitting object must intersect the plate.

Tip: Use Elements List to display the list of the splitting objects you selected. You can remove or replace the previously selected splitting objects. - Optional:

Click

in the

Splitting Object Toolbox to create a

sketch as the splitting object.

in the

Splitting Object Toolbox to create a

sketch as the splitting object.

- If the panel is planar, the sketch is created on the plane of the panel.

- If the panel is non-planar, the sketch is projected on the panel.

-

Click

OK.

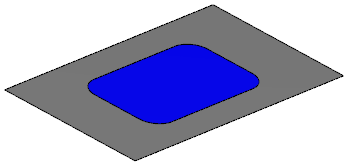

A seam is created on the panel. The panel is divided into plates. The largest plate after seam operation replaces the original plate in the plate set and inherits all its properties.

Important: The definition of an existing seam must be managed through the Seam  command

only.

command

only. -

Select a split plate in the

3D area

or in the

tree,

and click

Review Attributes

on the

context toolbar.

The Attributes panel appears listing all the attributes of the selected split plate.

on the

context toolbar.

The Attributes panel appears listing all the attributes of the selected split plate. - Optional:

Select an individual split plate in the

work area

and click

Edit Split Plate

on the

context toolbar.

The Split Plate panel appears displaying the name of the plate, material, thickness, and orientation.

on the

context toolbar.

The Split Plate panel appears displaying the name of the plate, material, thickness, and orientation. - Optional:

Modify the material, thickness, material orientation, or thickness

offset.

Notes:

- When the material is common between the split plate and the panel, replace the material directly by selecting a new material from the list.

- If you want to invert the material orientation of all split plates, invert the orientation of panel first.

- The thickness of the panel should fully include all the split plates. That is, the thickness of a split plate should not be more than that of the panel.

- Optional:

Click

OK.

The material and thickness of the plate are modified.