The selected elements are synchronized.

You can generate synchronization report in the form of an HTML file in the synchronization report repository by clicking the Generate Report button. For more information, see About the HTML Report.

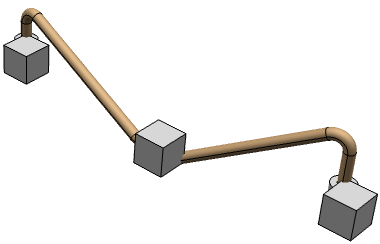

In the work area, the predefined parts are instantiated from the database.