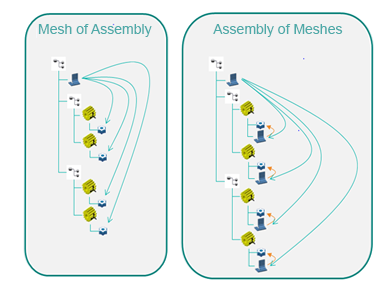

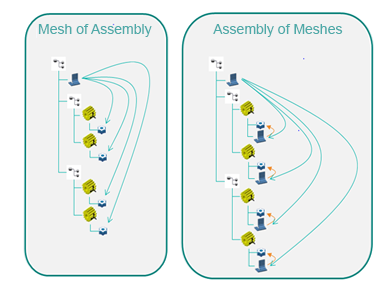

By default, the Automated FEM creates one child FEM representation for each leaf product to be meshed and one FEM

representation that assembles all the child FEM representations. This is known as an assembly

of meshes. Alternatively, you can change the Automated FEM execution options to create one FEM representation for the entire assembly (a mesh of

assembly). The

following image displays how each type of meshing references the geometry of each part in an assembly:

- Mesh of Assembly

- One mesh is created at the assembly level for geometry of the entire assembly. The mesh

references the 3D Shape representations for each part within the assembly to mesh the

entire assembly. This option can be faster to configure, but does not provide as much

control for specific parts of the mesh.

- Assembly of Meshes

- A mesh is created at the part level for each part in an assembly. Each mesh at the part

level references the 3D Shape representation for that part. There is also one mesh at the

assembly level that assembles the meshes for each part. With an assembly of meshes, you

can configure the FEM representation for each part. This can be useful to configure meshes

differently for parts with different geometries.