Mesh Control | ||

| ||

Mesh control refers to specifying different element sizes at different regions in the model. A smaller element size in a region improves the accuracy of results in the region of interest.

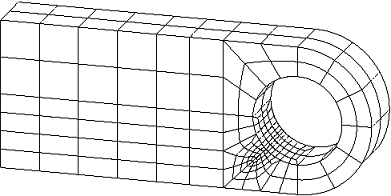

For example, the figure below shows a mesh that is designed to give an accurate prediction of the stress concentration at the bottom of the hole.

The results from the simulation with this locally refined mesh show that they are comparable to those from the very fine mesh. The simulation with the locally refined mesh required considerably less CPU time than the analysis with the very fine mesh.

| Mesh | Max displacement at bottom inner surface of hole (in) | Max von Mises stress at bottom inner surface of hole (psi) | Relative CPU time |

|---|---|---|---|

| Very fine | 3.15E-4 | 345.E6 | 22.5 |

| Locally refined | 3.15E-4 | 346.E6 | 3.44 |

You can often predict the locations of the highly stressed regions of a model (and, hence, the regions where a fine mesh is required) using your knowledge of similar components or with hand calculations. This information can also be gained by setting a coarse mesh initially to identify the regions of high stress and then refining the mesh in these regions. It is simple to mesh the geometry coarsely for the initial simulation and then to refine the mesh in the appropriate regions, as indicated by the stress results from the coarse simulation.