About Surface Finishes | |

| |

Roughness and Surface Finish Factor

You can express surface finish in terms of or , two parameters that describe roughness differently:

- , also known as the Arithmetic Average Roughness, describes the roughness of a surface by measuring the average height of irregularities (in µm) deviating from a mean line.

- describes roughness by describing the average vertical distance between the highest peak and the lowest depth within a set of samples.

| Surface finish option |

|---|

| Mirror polished ( ≤ 0.25µm) |

| 0.25µm ≤ ≤ 0.6µm |

| 0.6µm ≤ ≤ 1.6µm |

| 1.6µm ≤ ≤ 4µm |

| Fine machined (4µm ≤ ≤ 16µm) |

| Machined (16µm ≤ ≤ 40µm) |

| Precision forging (40µm ≤ ≤ 75µm) |

| Rough ( ≥ 75µm) |

These values are based on the following reference guide:

UNI 7670, Meccanismi per apparecchi di sollevamento, Ente Nazionale Italiano Di Unificazione, Milano, Italy.

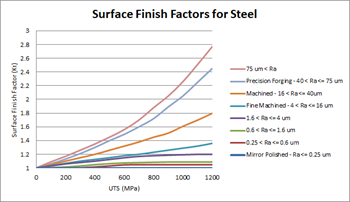

The effect of surface finish on the fatigue analysis is to convert the common surface finish qualities to a surface finish factor, . The app then uses to multiply the stresses of the elements on the surface of a body. The following figure illustrates how varies with surface finish and Ultimate Tensile Strength (UTS) for steels. As the figure shows, choosing a mirror polished surface finish has no effect on the analysis ( ).

You can convert the common surface finishes to factors for steels only. You can also specify the factor directly.

The predefined surface finish library RC Johnson includes surface finish values defined using . A new surface definition curve is generated by interpolating the existing data for the defined value and the material’s UTS is used to derive the value of from the generated curve. You can then obtain the surface finish factor by calculating .

Base Surface Finish and Local Surface Finishes

You can specify a base surface finish to define the roughness for the entire model and local surface finishes to define the roughness of selected regions. Local surface finish definitions override the base surface finish. In practice, you might want to apply a base surface finish first, then override for selected locations where the surface is more rough or more smooth than the default finish.

If you define two local surface finish definitions that overlap (that is, they share at least one surface), the rougher surface finish prevails for that surface. This approach enables you to calculate a more conservative fatigue life.