About Surface-Based Contact and Bonded Contact | |

| |

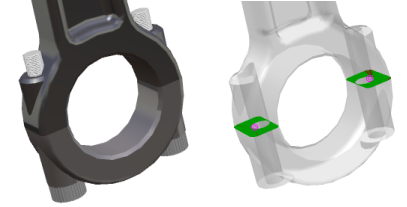

A bonded contact consists of two surfaces on two separate part bodies. These two surfaces remain firmly attached to one another during a simulation, as if they were glued or welded together. The surfaces might stretch, bend, or deform together during the simulation, but they never move relative to each other. Bonds represent the most basic connection between components, essentially joining two components into a single component at a common interface.

The two surfaces in a contact definition should be touching in the assembled product. However, if you define a bond between two surfaces that are separated by a distance, these surfaces still behave as if they are bonded together during the simulation. See About Proximity and Orientation Requirements.

Bonds accurately represent simple,

permanent connections, such as welds. You can also use a bond to approximately

represent simplified connections between two components that are fastened

together using other means. For example, if two components are bolted together,

you can define a bond between the contacting surfaces around the bolt; the bolt

no longer serves a purpose and can be removed from the assembly for the

simulation.