-

From the tree, double-click EXAMPLE-Driveshaft-Subassembly A.

The 3DEXPERIENCE platform returns to Model Assembly Design.

-

From the Automated FEM section of the action bar, click Automated FEM

.

.

The Automated FEM dialog box appears, indicating

the available methods for generating a FEM representation.

-

From the General Purpose methods, click User

Driven.

The Automated FEM: User Driven dialog box appears

and displays the structure of the model. The plane is hidden because it is an

abstraction shape, not a geometry that you can mesh.

-

Select the rows for both the hollow shaft and the support shaft.

-

Right-click the Procedure cell for one of the selected

rows.

-

From the context menu, click .

You can apply a submodel procedure only to the parts that extend through the submodel

boundaries. The submodel meshing procedure ensures continuity from the coarse

mesh of the global FEM to the finer mesh of the submodel FEM. In this example,

the hollow shaft and supportive shaft cross the plane that defines the submodel.

Therefore, you must define a submodel procedure for both of these parts before

meshing them.

-

Edit inputs for the submodel procedure.

-

Select the rows for both the hollow shaft and the support shaft, and

right-click the Procedure cell for one of the

selected rows.

-

From the context menu, click Edit Inputs.

-

For the Cutting surface, use the tree to expand , and select Plane.1.

-

Enter 5mm as the Mesh

size.

-

From the Element order options, select

Linear.

-

Enter 0.1mm as the Sag

value.

-

Select Create solid section.

You must create a solid section before you can apply a material

definition to the parts.

-

Click OK.

-

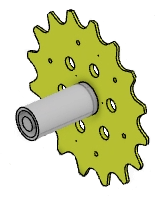

In the Automated FEM dialog box, select the rows for the

remaining parts in the submodel (that is, the sprocket, bearing, distance

washer, and bearing stopper).

These parts all belong to the submodel exclusively. They do not cross the

submodel boundaries.

-

Similar to the procedure you defined for the hollow shaft and the support

shaft, apply a procedure to these parts using a tetrahedron mesh, a 5-mm mesh

size, and a 0.1-mm sag to create the solid sections.

-

Click Run.

The Finite Element Model dialog box appears, showing the

solver's progress as it creates the FEM representations for the

parts.

-

When the process completes, click Yes to refresh the

session.

The

Automated FEM dialog box displays the results, and the

app updates the

3D area to show only the submodel. For visual clarity, the image below shows the

submodel without the meshes.

-

You may ignore bad elements in these meshes.

Bad elements indicate that a tetrahedron mesh element's shape is skewed or

stretched. Addressing bad elements is not within the scope of this

example.

-

Right-click the new FEM representation in the tree, and rename it Submodel FEM.

The 3D area

displays the submodel with all of its parts meshed. The app

meshed each part individually and collected the meshes to create the submodel

FEM.