-

Ensure that the analysis context is set to Submodel

Analysis.

-

From the Boundary Conditions section of the action bar, click Submodel Displacement

. .

This feature transfers the displacement degrees of freedom from the global

model to the submodel along their shared boundaries, such that the submodel

motion follows that of the global model.

-

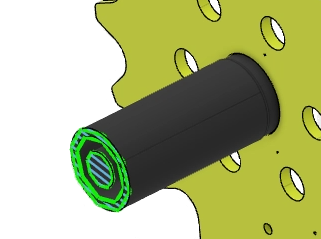

Select the cut faces at the ends of the hollow shaft and the supportive

shaft.

-

From the tree, expand the shaft parts.

-

Select the submodel FEMs (that is, the second FEM in each part).

-

Hide the meshes.

-

In the 3D area, select the cut faces of the shaft parts.

-

For the Global Step, select Static

Step.1.

-

Click OK.

-

Change the analysis context to Global

Analysis.

-

From the Loads section of the action bar, click Force

. .

-

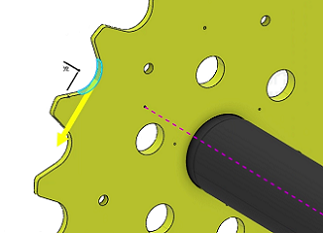

Select one of the valleys between the gear teeth on the sprocket, and enter

-1000N in the global Z-direction.

The app applies the force, as shown below. The force transfers from the sprocket

teeth to the driveshaft as a pure rotational force.  -

From the Boundary Conditions section of the action bar, click Fixed Displacement

. .

-

In the 3D area, select the end of the support shaft that is furthest from the

sprocket.

-

Select

the X, Y, and Z rotational and translation degrees of

freedom, and click OK.

The restraint is shown below.  -

Change the analysis context to Submodel

Analysis.

-

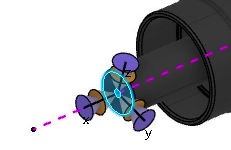

Similarly, create a restraint on the end of the support shaft that is closest

to the sprocket.

The

displacement restraints for the submodel use only one end of the shaft.

The

submodel displacement load supports the shaft at the boundary between the global

model and the submodel.

|