-

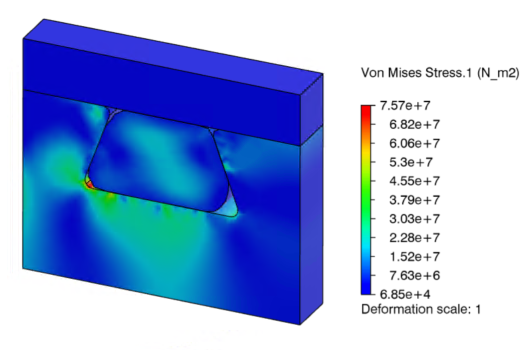

When the simulation completes, Physics Results Explorer displays the von Mises stress contour plot for the last solution step.

The global max of the von Mises stress value is 7.57e+7 N/m2, which is

less than the material yield value of 2.068e+8 N/m2.

-

To display the maximum value in a contour plot, do the following:

-

From the Display section of the action bar, click Show Min/Max values

.

.

-

In the context toolbar, select Show only Max value

, and click OK

, and click OK

.

.

-

To display the displacement plot, do the following:

-

In the Plots panel, from the

Plot options, select

Displacement.1.

-

Select the last row to display the results of the last time increment

in the static step.

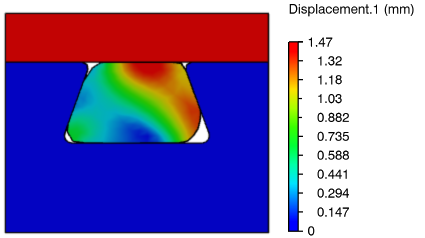

The top plate has a maximum displacement of 1.47 mm, as expected. The deformed

shape of the O-ring indicates that it stretches laterally as the top

plates pushes it into the groove. The O-ring's maximum compression ratio

is 1.47 / 5.64 = 26%, which is an acceptable ratio (5.64 mm is the

largest diameter of the undeformed O-ring's cross-section). For most

elastomer O-rings used as static seals, the maximum recommended

compression ratio is 30%.

-

Display the contact pressure contour plot, and configure it to show only the

results of the O-ring.

-

In the Plots panel, from the

Plot options, select Contact

Pressure.1.

-

From the Display section of the action bar, click Display Group

.

.

-

Clear the Top plate and

Groove options.

-

Click Replace selected

to display only the O-ring's results, and click

Close.

to display only the O-ring's results, and click

Close.

The contact pressure results are visible for the O-ring only. The

contact pressure is highest at the top and bottom surfaces of the O-ring, and

considerable pressure developed between the side surfaces of the O-ring and the

groove walls. The O-ring seals the vacuum chamber efficiently.

The percentage

of volume that an O-ring's cross-section displaces in its confining space

(or gland) is called “gland fill.” Most O-ring seal applications require a

gland fill between 60% to 85% of the available volume, with an optimum fill

being 75% (or 25% void). It is essential to allow at least a 10% void in any

elastomer sealing gland to compensate for thermal expansion and O-ring

swell.

-

Save your work.

Congratulations, you have successfully completed this example!