-

From the options at the top of the Calibration Setup

panel, click Execute

. .

This example uses the default best-fit error measure (the coefficient of

determination, R2) as a convergence criterion measure. This measure

indicates how closely the calibration curve matches the test data points. For

R2, the objective function value is a number between 0 and 1; the

closer to 1, the better the match. The objective function is a measure of the

error between the test data and the predicted material response.

The Calibration History panel appears and provides a plot of

the progress of the calibration, including the value of the objective function

for each iteration.

-

After the calibration completes, review the data in the

Sensitivity column in the Material

model section of the Calibration Setup

panel.

All of the parameters have low

sensitivities

except C10 and g5. However, there is little room for

improvement

because the R2 values are already high.

-

Review the convergence criterion values at the bottom of the

Calibration Setup panel.

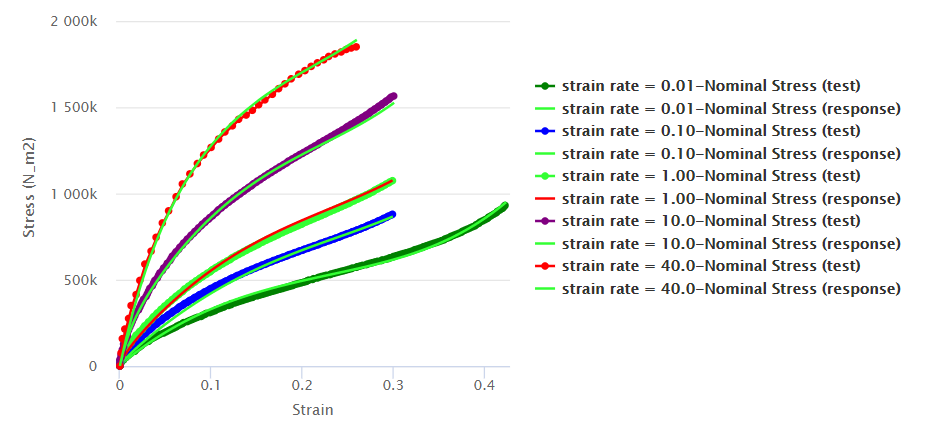

Each material response simulated from the calibration demonstrates R 2

values of over

0.99,

indicating that the calibration is representative of the material behavior.

Review the table below to see the sample results of the

calibration.

| Model and Test Data |

Weight |

R2 |

| Strain Rate = 0.01 |

1 |

0.997 |

| Strain Rate = 0.10 |

1 |

0.993 |

| Strain Rate = 1.00 |

1 |

0.998 |

| Strain Rate = 10.0 |

1 |

0.999 |

| Strain Rate = 40 |

0.5 |

0.998 |

-

Review the updated response curve in the Plot panel.

The material response curve is closer to the test data, as shown below. In this

example, the color of the response curves has been changed to green.  -

Save your work.

|