Bend Allowance

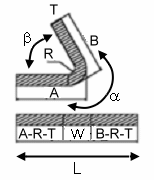

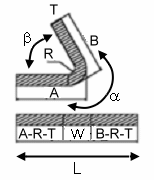

The bend allowance corresponds to the unfolded bend width.

L is the total unfolded length.

A and B are the dimensioning lengths as defined on the above figure. They are similar to the DIN definition.

Bend AllowanceThe bend allowance corresponds to the unfolded bend width.   L is the total unfolded length. A and B are the dimensioning lengths as defined on the above figure. They are similar to the DIN definition. K FactorPhysically, the neutral fiber represents the limit between the material compressed area inside the bend and the extended area outside the bend. Ideally, it is represented by an arc located inside the thickness and centered on the bend axis. The K factor defines the neutral fiber position: W = a * (R + k * T) where: W is the bend allowance R the inner bend radius T the Sheet Metal thickness a the inner bend angle in radians. If b is the opening bend angle in degrees: a = p * (180 - b) / 180

When you define the Sheet Metal parameters, a lateral feature defines the default K Factor and a formula is applied to implement the DIN standard. This standard is defined for thin steel parts. Therefore the K Factor value ranges between 0 and 0.5.

This formula can be deactivated or modified by right-clicking in the K Factor box and choosing an option from the context menu. It can be re-activated by clicking DIN calculation. Moreover, the limit values can also be modified. When a bend is created, its own K Factor literal is created. Two cases may then occur:

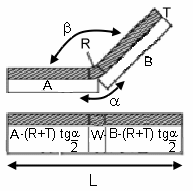

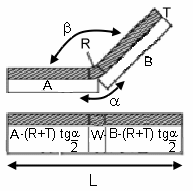

Bend DeductionWhen the bend is unfolded, the Sheet Metal deformation is represented by the bend deduction V. The bend deduction V is defined by the formula: L = A + B + V Then, the bend deduction is related to the K factor by the following formula: V = a * (R + k * T) - 2 * (R + T) * tan ( min(p/2,a) / 2) This formula is used by default. However, it is possible to define bend tables on the Sheet Metal parameters. These tables define samples: thickness, bend radius, open angle, and bend deduction. In this case, the bend deduction is located in the appropriate bend table, matching thickness, bend radius, and open angle. If no accurate open angle is found, an interpolation is performed. When updating the bend, the bend deduction is first computed using the previously defined rules. Then the bend allowance is deduced using the following formula: W = V + 2 * (R + T) * tan ( min(p/2,a) / 2)

| |||||||||||