Create a Standard Cutout

Before you begin: Create a wall that has closed

sketch on it.

-

From the Sheet Metal section of the action bar, click Cutout

.

.

-

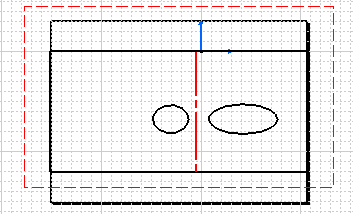

In the Cutout dialog box, click

Standard

and

from the work area, select a sketch as a profile.

and

from the work area, select a sketch as a profile.

-

For Limit type 1 and Limit type

2 lists, select one of the following:

Option Description Dimension Creates the cutout using a depth value. Up to next Creates the cutout up to the next surface. Up to last Creates the cutout up to the last surface.

When you drag the handle, you can see the preview. Shaded preview appears on the release of the handle. The area in sheet metal where the cut happens have preview in the yellow color.

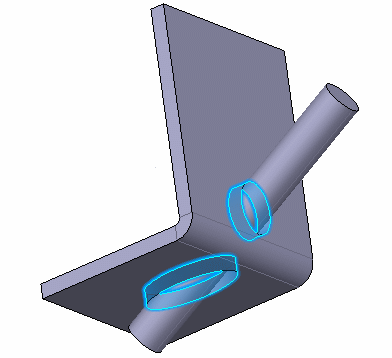

In the above image, the Limit value is Up to Last. By default, the Limit to thickness check box is selected.

-

Under Cutout direction, select the following

options:

- Click Direction to specify the cutout direction.

- Click Revert cut direction to invert the direction of an extrusion.

- Click Revert material side to invert the direction of a material side.

-

Under Impact Options, from the Face

type list, select one of the following:

- Top to select the top face to begin with the cutout.

- Bottom to select the bottom face to begin with the cutout.

-

Click Faces to select specific face with selected

face type to that you want to cut out.

If you do not select any face, by default all the faces are selected for cutout.

-

Click

to

save and exit.

to

save and exit.

Note: You can use equations for all numeric parameters. Click the dimension text. The dimension text becomes editable. Type = in the input field, to open the Equation dialog box and enter a formula or number..

Note: You can use equations for all numeric parameters. Click the dimension text. The dimension text becomes editable. Type = in the input field, to open the Equation dialog box and enter a formula or number..