Creating a Concept to Detail Link | ||

| ||

A link feature is created in the detailed part.

- Its name is Link to: <Reference Feature Name>

- It is created under a geometrical set, with the same name as the reference feature.

- It creates a data model that depends on the reference feature, as explained below.

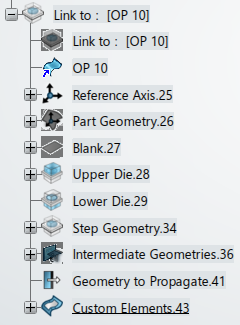

If linked to a process step

- Reference Axis set

- Reference Press Axis

- Reference Blank Axis: Blank axis without swiveling

- Reference Part Axis: All the part axes without swiveling

- Step Press Axis: Reference press axis translated to the OP position

- Step Blank Axis: Blank axis translated to the process step position, with swiveling

- Step Part Axis: Part axis, translated to the process step position, with swiveling

- Proxy Step Blank Axis: Step Blank axis translated from the step press axis to the reference press axis

- Proxy Step Part Axis: List of step part axes translated from the step press axis to the reference press axis

- Part Geometry

- Copy of the input part (result of the process)

- Copy of all additional elements, if the input part is a process positioning feature.

- Blank

- Copy of each blank section

- Upper Die

- A concept to detail link for each Tool of the OP in the Upper Die.

- Lower Die

- A concept to detail link for each Tool of the OP in the Lower Die

- Previous Step Detailed Geometry

- If detailed geometry was specified in the previous process step, it is copied in the current process step, with the right position and swiveling. Part swiveling is not applied.

- Step Geometry

- A Concept Geometry set: Concept result geometry out of the process step

- A Design Geometry set: Specifies the intermediate features used to design the step resulting detailed geometry.

- A Detailed Geometry set: Specifies the step resulting detailed geometry.

- Intermediate Geometries: List of flanges/intermediate geometries from the future OP, allowing the computation of the realistic trim line, for example , organized in sub sets Intermediate Geometries, Flange Areas, Stamped Areas.

- A concept to detail link for each custom geometry of the step.

- Geometry to Propagate set: Specifies the features propagated by the detail to detail link.

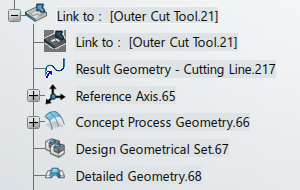

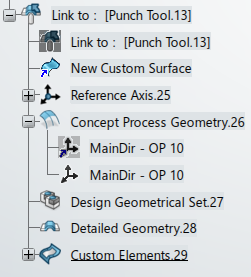

If linked to a process tool

- A Concept Process Geometry set

- Copy of the tool direction

- Copy of the input geometries

- A Design Geometrical Set: Specifies the intermediate features used to design the tool resulting detailed geometry.

- A Detailed Geometry set: Specifies the tool resulting detailed geometry.

- A concept to detail link for each custom geometry of the tool.

If linked to custom geometry

- A Concept Process Geometry set: Copy of the custom concept geometry.

- A Design Geometrical Set: Specifies the intermediate features used to design the custom geometry detailed geometry.

- A Detailed Geometry set: Specifies the resulting detailed geometry.